Industry pumps for a wide range of industrial applications

Rotary lobe pump of the VX series for industrial applications

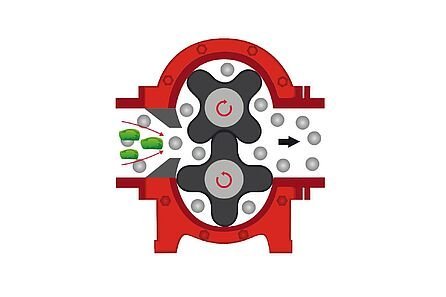

The rotary lobe pumps in the VX series are the perfect solution for a variety of industrial applications. For example, they can be used to pump viscous media such as oil in the petrochemical industry or molasses in the sugar industry. Fluids such as those in the wine industry, with a high solids content like sediment or pomace, can be pumped as effectively as wastewater oils in recycling applications or media in a potentially explosive environment (ATEX). With their resistance to dry running and their ability to pump in either direction of rotation, the industry pumps of the VX series are the ideal solution for filling and unloading tanks in storage areas, tankers or ships.

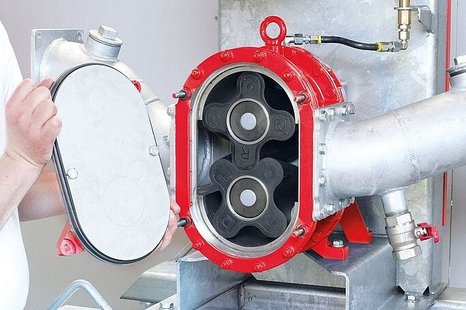

The compact and space-saving design means that these rotary lobe pumps can be integrated into any system. Thanks to further innovations, such as the patented InjectionSystem or the unique HiFlo lobes, industry pumps in the VX series guarantee maximum efficiency in operation. We also developed the QuickService concept to further increase the availability of your plant. Maintenance work can be performed quickly and on site, without having to dismantle the rotary lobe pump. With five different series and more than 25 different sizes for this sturdy, technically advanced, well-constructed and powerful pump technology, we offer the perfect pump for any application.

Downloads

Features of the VX series

Options of the VX series