Technology for sewage treatment plants

Reliable pump technology and trouble-free wastewater and sludge treatment

Wet wipes, debris, and tough sludge don’t stand a chance when Vogelsang puts Vogeltron on the job. From clogged pumps to inefficient dewatering equipment, wastewater challenges can quickly turn into costly downtime. That’s why our pumps, grinders, and macerators are built to be the heroes of your operation—reliable, resilient, and always ready.

Reliable pump and grinder technology for wastewater applications, including:

- Wastewater Headworks

- Septage & FOG

- Abrasive primary sludge/raw sludge

- Secondary sludge/surplus sludge

- WAS/TWAS

- Digester Operations

- Dewatering feed, thickening

It is important here to use reliable and trouble-free pump technology that is designed for this wide range of media.

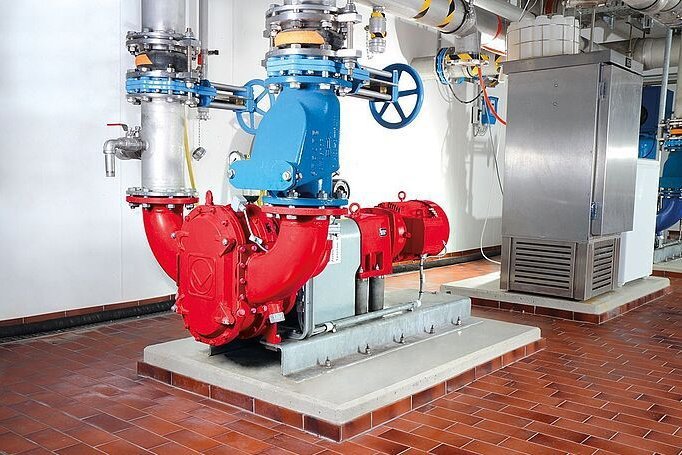

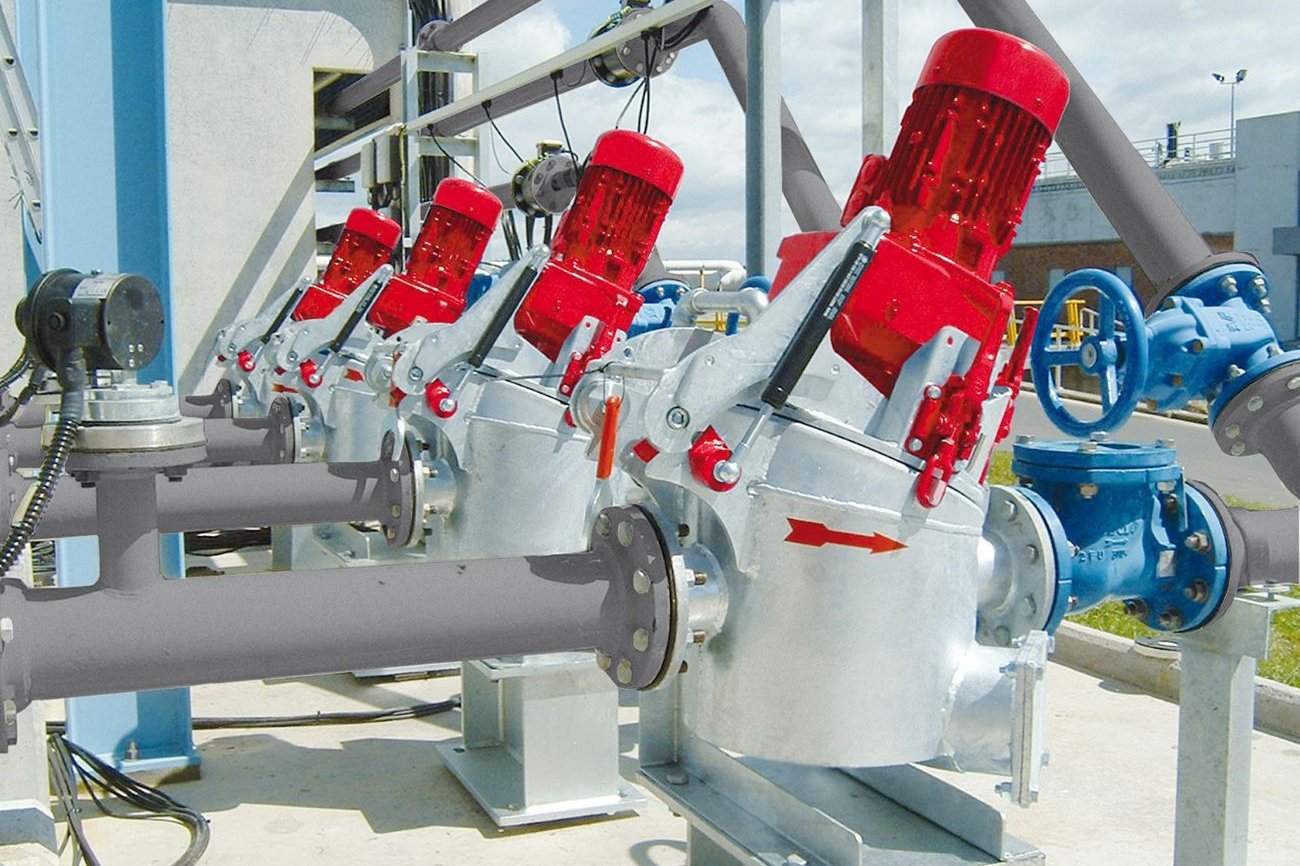

Universal wastewater pump for diverse tasks

Wastewater treatment plants find that Vogelsang pumps make a great standardized option as they work well in numerous applications. The benefit here with the Vogelsang rotary lobe pump is the simple changeover of the direction of flow while the pump capacity remains the same. In this way, using a single pump, wastewater, and sludge can be recirculated between tanks and sump or fecal matter removed from disposal vehicles or tankers filled with sewage sludge. Since the delivery rate is proportional to speed, the efficiency can be variably adjusted via the variable frequency drive while the delivery rate remains the same. By taking into account dry matter content and the viscosity of a medium, pipe diameter, and pipe length, the delivery rate of wastewater pumps and sludge pumps can be adapted individually. In practice, this means feeding of digestion towers, thickening, and drainage is regulated and efficient, yet at the same time, delivery with high pressure or over large distances is also possible. In particular when it comes to circulation in digesters, a high pump capacity makes a positive difference where space requirements are at a premium since little room is often available here for installation of a pump.

Cut, shred, grind, and kiss your solids goodbye.

When it comes to handling solids, Vogelsang is not a one-trick pony. We have multiple lines, covering everything from large channel grinders for headworks to macerators for refined shredding and sludge conditioning aimed at protecting dewatering equipment and digester processes. This ensures we have a tailored solution for type of solids handling you need.

Heavy solids: Twin-shaft Grinders

For headworks channels, lift stations, primary sludge, and septage receiving, turn to XRipper, our robust twin-shaft grinder. For wood, wipes, plastics and other heavy solids that might pass screening systems, XRipper provides maximum protection to pumps and process equipment.

Don’t shred when you need to cut.

When it comes to fibers, hair and other waste that slips through screening units, a grinder will not be the best solution. This is where our RotaCut macerator steps in. This technology is designed with a spinning blade and screen that ensures all solids are cut to a specific particle size. What’s more? It also acts as a sludge conditioner and heavy solids trap. This ensure sludge fed to dewatering equipment and digesters is both free of foreign objects and fed as a homogenized slurry for improved processing.

Choose RotaCut for:

Secondary, TWAS, Sludge transfers

Dewatering feed / sludge thickening preparation

Digester feed line and sludge recirculation, heat exchangers

Septage / FOG receiving stations