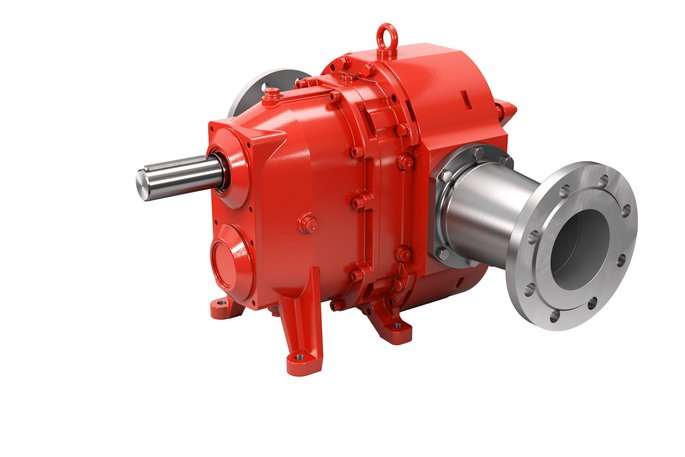

Rotary lobe pump for highest efficiencies

VY series

- High efficiency even with demanding media

- One-piece housing with low dead space

- Compliance with industry-specific standards through new sealing options

- ATEX and TA-Luft compliant

The versatile with high efficiency

The VY series rotary lobe pumps for maximum energy efficiency

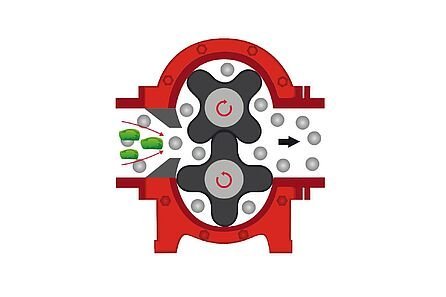

As customers from the chemical and process industry or the food sector will tell you, who have long relied on Vogelsang‘s trusty rotary lobe pumps: you can depend on this technology. And not only because the pumps effortlessly transport abrasive, aggressive, viscous, or contaminated media such as paint, sugar, wine or raw materials for the construction chemistry from A to B. Depending on your requirements, you can choose between different sizes, delivery rates, speeds, and differential pressures.

With the rotary lobe pumps of the VY series, Vogelsang remains true to these characteristics, which are very important for the economic efficiency of a pump. However, to better meet the highly demanding applications of industry, the housing of these pumps is designed in one piece and with a minimum of sealing points, like that of the EP series pumps. This manufacturing technique results in a high-precision, flow-optimized end product that is highly efficient even with difficult media. The VY housing is also low in dead space and prevents the accumulation of residues.

Models of the VY series

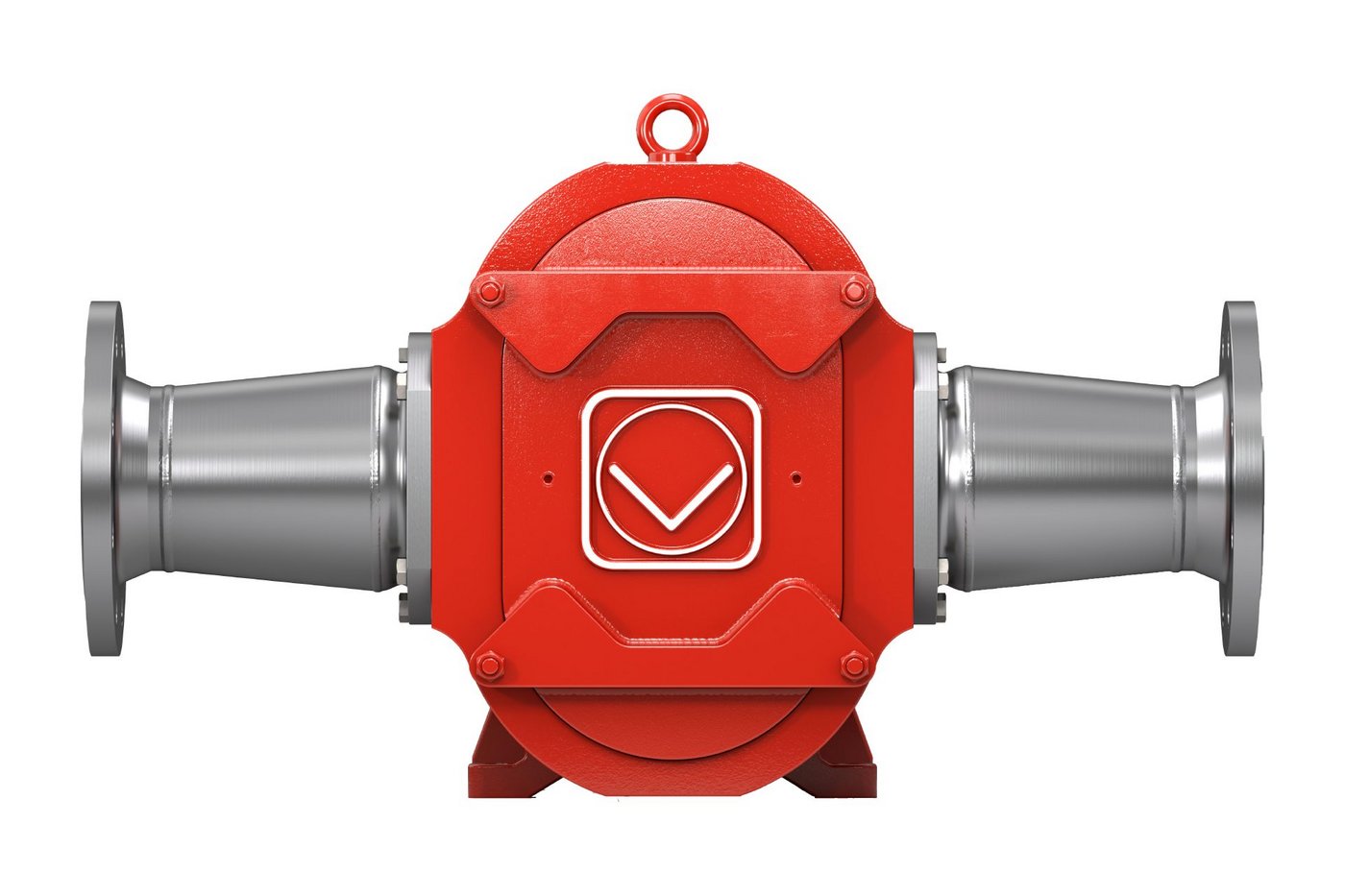

The compact pump

Rotary lobe pump VY100

With the launch of its new VY series, Vogelsang is introducing a rotary lobe pump for demanding industrial applications. Its high-precision, one-piece housing features a minimum number of sealing points and is flow-optimized, which ensures high efficiency, even with difficult media.

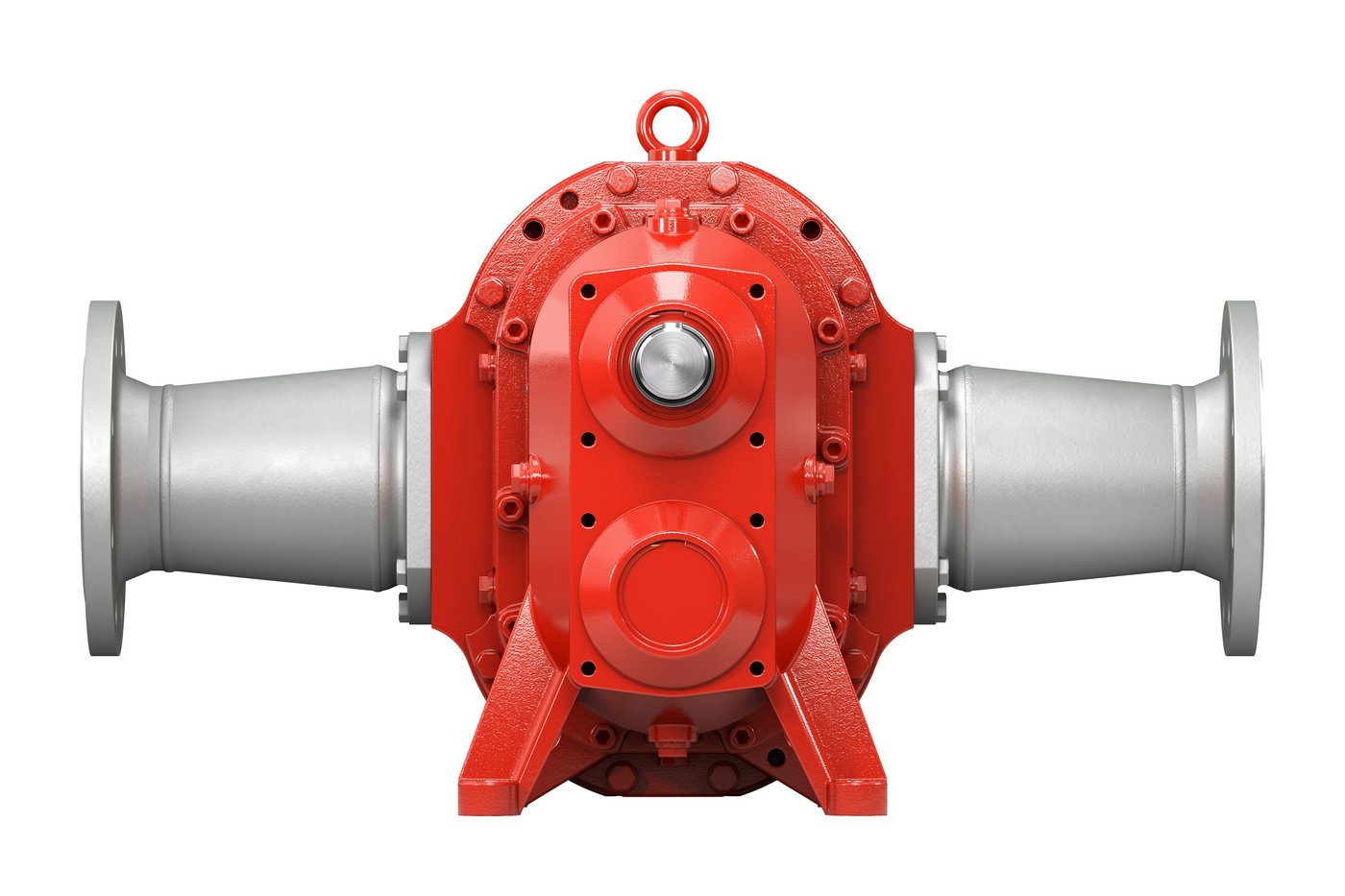

The efficient pump

Rotary lobe pump VY136

The housing of all VY pumps is low in dead space and can be flushed and disinfected in accordance with the requirements for CIP or SIP conformity. Their performance ranges from 1 m³/h to 120 m³/h at a maximum pressure of 10 bar. In addition, the VY series offers the possibility of using a variety of sealing options for a wide range of applications.

The compact pump

Rotary lobe pump VY100

With the launch of its new VY series, Vogelsang is introducing a rotary lobe pump for demanding industrial applications. Its high-precision, one-piece housing features a minimum number of sealing points and is flow-optimized, which ensures high efficiency, even with difficult media.

The efficient pump

Rotary lobe pump VY136

The housing of all VY pumps is low in dead space and can be flushed and disinfected in accordance with the requirements for CIP or SIP conformity. Their performance ranges from 1 m³/h to 120 m³/h at a maximum pressure of 10 bar. In addition, the VY series offers the possibility of using a variety of sealing options for a wide range of applications.

Applications for the high efficient VY series

The VY rotary lobe pumps are based on Vogelsang’s proven VX series. Different seals can also be variably used in the new housing – depending on industry-specific standards and requirements. This makes the VY series an all-rounder for use in, for example, the chemical industry as well as in the paper and textile sectors. The performance spectrum of the VY pumps ranges from 1 m³/h to 120 m³/h at a maximum pressure of 10 bar. Integrated sensors provide all the important information about the pump’s operating status. For media with abrasive components, the VY series is available with axial and radial wear protection.