RotaCut®: Trouble free dewatering

Case Study: hanseWasser Bremen GmbH

Problem

Malfunctions of centrifuges in dewatering

Solution

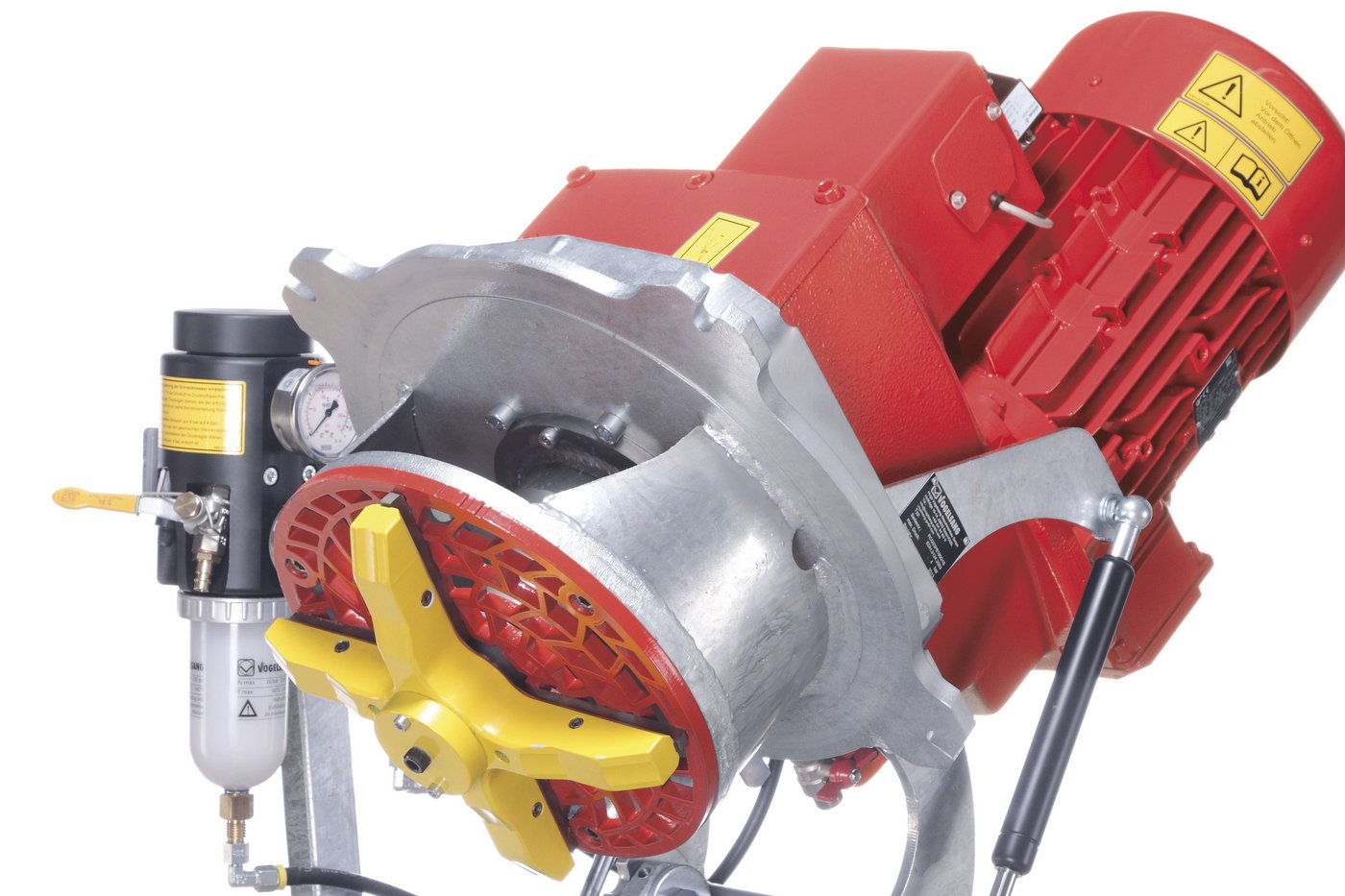

RotaCut RC 5000 Inline with ACC

The customer and the problem

hanseWasser Bremen GmbH operates 2,300 km public wastewater sewers as well as two WWTP in Farge and Seehausen. Both plants together serve over one million PE each year, 50 million m³ wastewater is treated and 16,000 tons sewage remains. However, WWTP Seehausen is designed for a peak capacity of 1 million PE. On average 130,000 m³ of wastewater is cleaned every day. When charging the two centrifuges for dewatering, malfunctions are often caused by entangled fibers and other fibers in the sludge.

The solution

"We installed two RotaCut Inline macerators with ACC in front of the centrifuges to treat the sludge before feeding to the centrifuges. Thanks to the homogeneous sludge without long fibers, malfunctions are avoided and dewatering runs safer,” said Mr. Weddermann from hanseWasser.

RotaCut reliably chops down all fibers and rags in the sludge. The ACC adjusts the blades automatically keeping an even pressure at all times. Furthermore, the sludge is homogenised in the process, which provides smooth operations of the centrifuges. Malfunctions, operational interruptions and unnecessary maintenance for trouble shooting are avoided with RotaCut and ACC.

Advantages of the RotaCut®

- Reliable maceration of fibers and rags

- Sludge is homogeneous and flow able

- Automatic blade adjusment

- Protects equipment and ensures trouble free and smooth operation of dewatering