XRipper®: Preparation of organic waste for use in a biogas plant

Case Study: Bioenergie Bamberg GmbH & Co.KG

Problem

Damage to pumps as a result of soiling

Solution

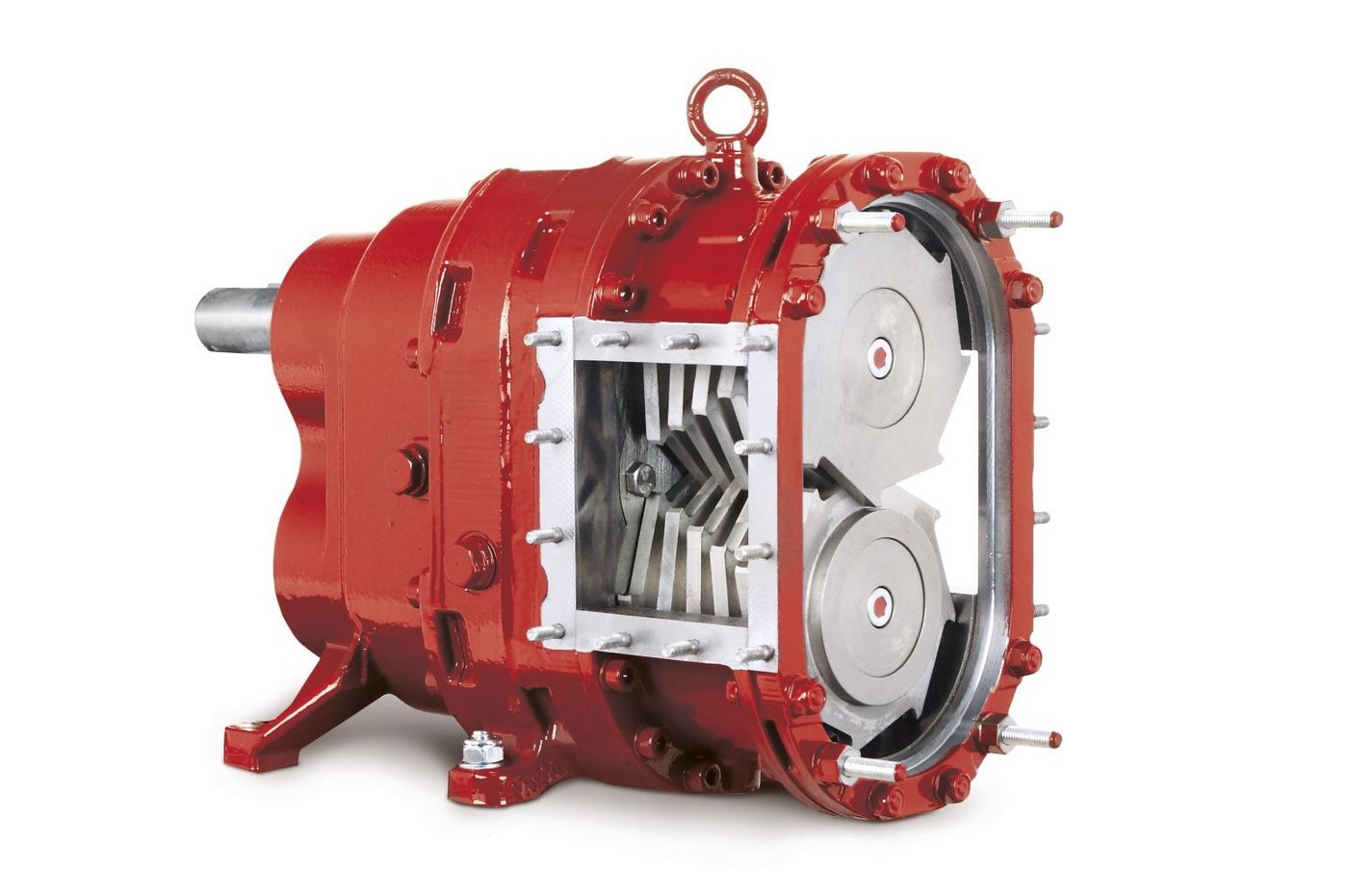

XRipper XRS136-105Q

The customer and the problem

Bioenergie Bamberg GmbH & Co.KG operates a biogas plant which has been producing energy and heat using biomass since September 2005. The source material consists of waste from the organic waste bins of households in Bamberg and the surrounding area. On average, 50 tons of biomass are processed each day.

The source material is pretreated and very coarse matter is removed. However, grit, sand and other coarse matter such as pieces of wood or cutlery remain present in the source material. For further processing, Bioenergie Bamberg was in search of a grinder to shred the material before it reaches the separator so that it no longer clogs the separator screw and leads to malfunctions.

The solution

The XRipper XRS136-105Q was chosen for this task. In close collaboration with Vogelsang, the process was optimized further and the service time of the ripper rotors increased. If the ripper rotors ever do have to be replaced, the Quick-Service concept allows for fast, on-site servicing and maintenance without having to remove and disassemble the XRipper. This ensures a high level of availability and keeps interruptions in operation to a minimum.

"The XRipper accomplishes the task as desired; we're happy," sums up company director Jörg Stadter.

Downloads

Advantages of the XRipper

- Long service times thanks to rugged design

- High availability thanks to quick servicing and easy maintenance

- Efficient protection against cutlery and pieces of wood