Farmer pump for liquid manure

FX series

- No additional lubrication required due to integrated circulating oil lubrication

- Industrial-standard block ring seal for long lifetime

- Self-priming and resistant to foreign bodies

- Quiet running thanks to well-conceived positioning of the lobes

- Low energy consumption thanks to rotating separation plate

Making the basics better

The FX series makes everyday life easier and reduces operating costs

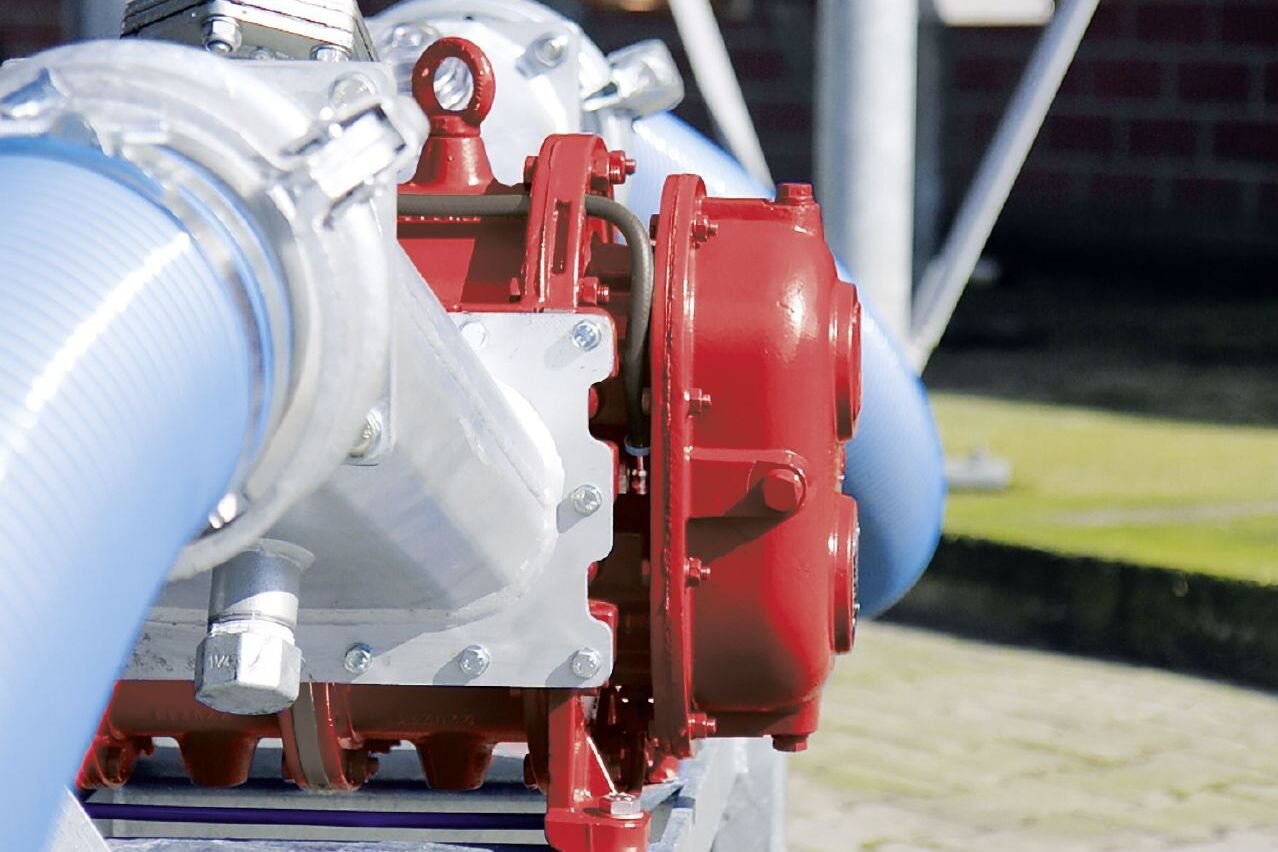

The FX series by Vogelsang was developed specially for the needs of farmers. It fulfills the special requirements of liquid manure as the medium, is easy to operate and is highly economical in operation thanks to its quality and ease of maintenance. As a professional liquid manure pump without torque boost, it offers a max. performance of 8 bar and a max. 4,500 l / min.

Lubrication no longer necessary: Sometimes it’s the little things that make a pump part of the FX series: Vogelsang eliminates lubrication from your list of jobs. Simple and effective oil circulation lubrication means that all gaskets are constantly lubricated and the grease gun remains on the shelf.

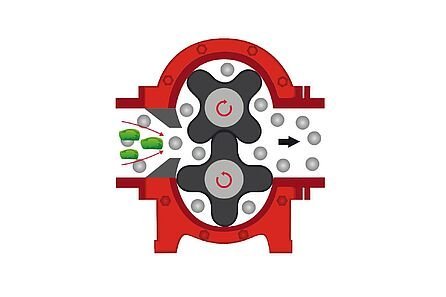

Pump liquid manure professionally without increasing torque: Liquid manure contains a lot of fibrous material that gathers in gaps and cavities and can increase the torque. This increases wear, wastes pumping power and ultimately energy. The FX series rotates the separation plate with the pistons: one less fiber trap, combined with greater pump power and lower diesel or electricity consumption.

Block ring seals for longer pumping times and reduced service times: Mechanical seals are significantly more durable than radial shaft seals. The FX series uses Vogelsang’s specially developed block ring variant of the mechanical seal. The special block increases the pump’s resistance to fibers in the liquid manure even further.

Features of the FX Series

The flexible farmer pump for agricultural applications

The FX series, or FarmerPump, is Vogelsang's liquid manure pump. It was custom-developed for agricultural use, and makes pumping easier at a reasonable cost. The upgraded product from the proven R series has an industrial-standard block ring seal, a rotating separation plate and a circulating oil lubrication system integrated as standard. That makes the FarmerPump ideal for everyday routine work on the farm.

The FarmerPump is also flexible in application: It can be operated anywhere via a power take-off, for example as a permanent installation, or as a mobile unit with the three-point base.

The rotating separation plate between the lobes prevents the accumulation of fibrous matter in the liquid manure. This maintains the full pump performance and minimizes diesel or electricity consumption. This rotary lobe pump is a professional liquid manure pump with no torque increase. Its performance range was specially designed for agricultural use, with six expansion stages up to max. 8 bar and max. 4,500 l/min.

Downloads