The gearless rotary lobe pump

GL series

- Up to 51 % less weight and up to 28 % less space

- Easier service

- Lower power consumption

- Incredibly quiet running

Reduced to the core of the matter

The new GL series: More compact and lightweight than ever before

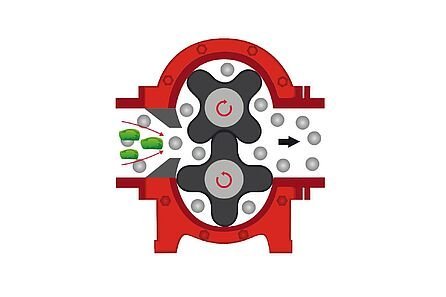

Less weight and smaller dimensions with the same performance – the new aluminum rotary lobe pump without gearbox is a real space-saving miracle. The GL series weighs less than half as much as previous comparable rotary lobe pumps from Vogelsang and is an impressive 25 cm shorter thanks to the hydraulic motors, which are flanged directly in the housing – a decisive advantage for integration in tankers!

About the GL series: The range of pumps in the GL series is extremely diverse and meets a wide variety of needs. The design ensures reliable flow performance and a long service life, no matter how tough or aggressive the medium to be pumped may be or how high the throughput must be.

More inside, less outside: Vogelsang’s pumps are certainly highly prized by the agricultural industry for their versatility and compact dimensions in relation to performance. With this new design, the GL series is now up to 25 cm shorter than the previous models of the VX series with external gearbox. This more compact design not only simplifies installation on mobile machinery. Combining the GL series with the aluminum construction allows weight savings of up to 140 kg. Comparing the new GL series with models from other manufacturers, this innovative Vogelsang design saves up to 51% in weight. A value that speaks for itself.

Models of the GL series

The GL series pump, more compact and lighter than ever before

Rotary lobe pump GL186

Robust and powerful – these are the hallmarks of the GL186 series. Already familiar from the VX series, the rotary lobe pumps in the GL series are just as powerful. The series is currently available in two different sizes. It is used primarily in mobile applications where space is limited and a low empty weight is required, but large quantities must be reliably conveyed. Field-proven equipment options for the GL rotary lobe pump, such as the proven radial wear plates, also allow for applications under extremely demanding conditions. At the same time, an even easier service is convincing, in which the pistons can be removed individually.

Downloads

The GL series pump, more compact and lighter than ever before

Rotary lobe pump GL186

Robust and powerful – these are the hallmarks of the GL186 series. Already familiar from the VX series, the rotary lobe pumps in the GL series are just as powerful. The series is currently available in two different sizes. It is used primarily in mobile applications where space is limited and a low empty weight is required, but large quantities must be reliably conveyed. Field-proven equipment options for the GL rotary lobe pump, such as the proven radial wear plates, also allow for applications under extremely demanding conditions. At the same time, an even easier service is convincing, in which the pistons can be removed individually.

Downloads

Features of the GL series

Options of the GL series