VX series with ASU system: for discharging dense food liquids

Case Study: SL di Liverani Srl

Problem

Lot of wear on mechanical seal

Solution

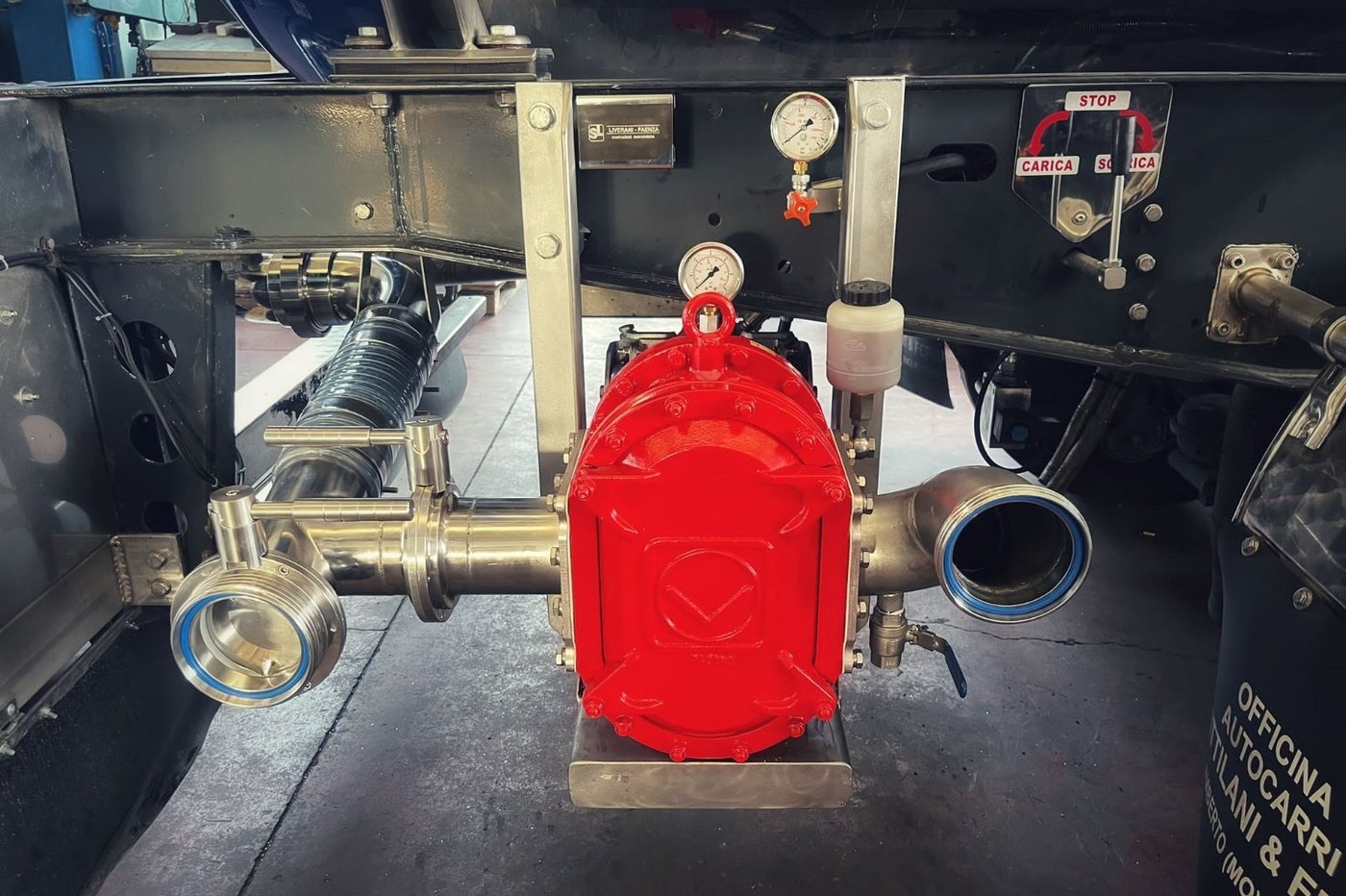

Changing to a rotary lobe pump VX136-140Q with ASU system

The customer and the problem

The SL company of Liverani has been operating in the field of mechanical constructions since 1974. It offers services for companies and individuals, comprending lobe pumps for discharging dense food liquids with or without hydraulic or electric inverter transmission and Volumetric pumps for food liquids.

One of his customer had mounted a Jurop VL20 pump with hydraulic motor on his truck to pump a ceramic product named “ingombbio or barbottina”. The problem was that the mechanical seals of this pump had to be overhauled and replaced after 1-2 months of operation (5-6 hours/day for 5/7 days/week).

The solution

In cooperation with our customer SL di Liverani we have decided to instal a VX136-140Q to replace the Jurop VL 20 with hydraulic motor. To improve the lifetime of the mechanical seals we have decided to use our mechanical seal Quality Cartridge WC/Sic together with the new system ASU (automatic supply unit). The task of the seal supply system ASU is to keep the lubricant in a seal at a constant level and to maintain the pressure of the buffer chamber pressure within the seal.

Advantages of the VX series

- Comprehensive range of features and options

- Self-priming and dry-running resistant

- Shaft warranty

- Quick access to the pump chamber by removing the cover

- Simple service and maintenance

Benefits for the user

- After 10 months of work the trucker is very happy how the pump operates

- So far there was no need to overhaul or replace the mechanical seals

- The performance of the pump has improved and he is saving time and costs on his charge/discharge cycles

- Quiet operation cycles

- Oil consumption of the hydraulic motor has decreased