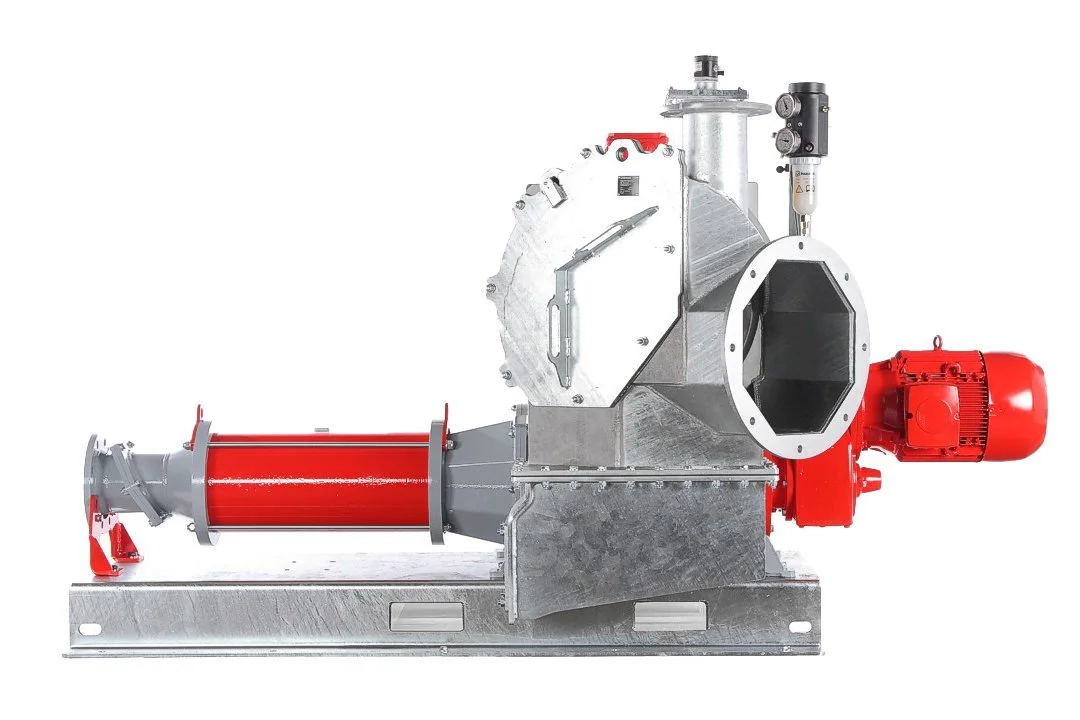

The universal 4-in-1 solid matter feeder

PreMix®

- Mashes a wide variety of biomass to a homogeneous organic suspension

- Separates out heavy material and shreds the solids before the pump unit

- Compact dimensions and easy to link in so its integration is uncomplicated

- Easy to feed several digesters with just one PreMix

- Easy and quick service on site

PreMix® Next Generation

The versatile PreMix® - Now even more powerful, efficient and durable

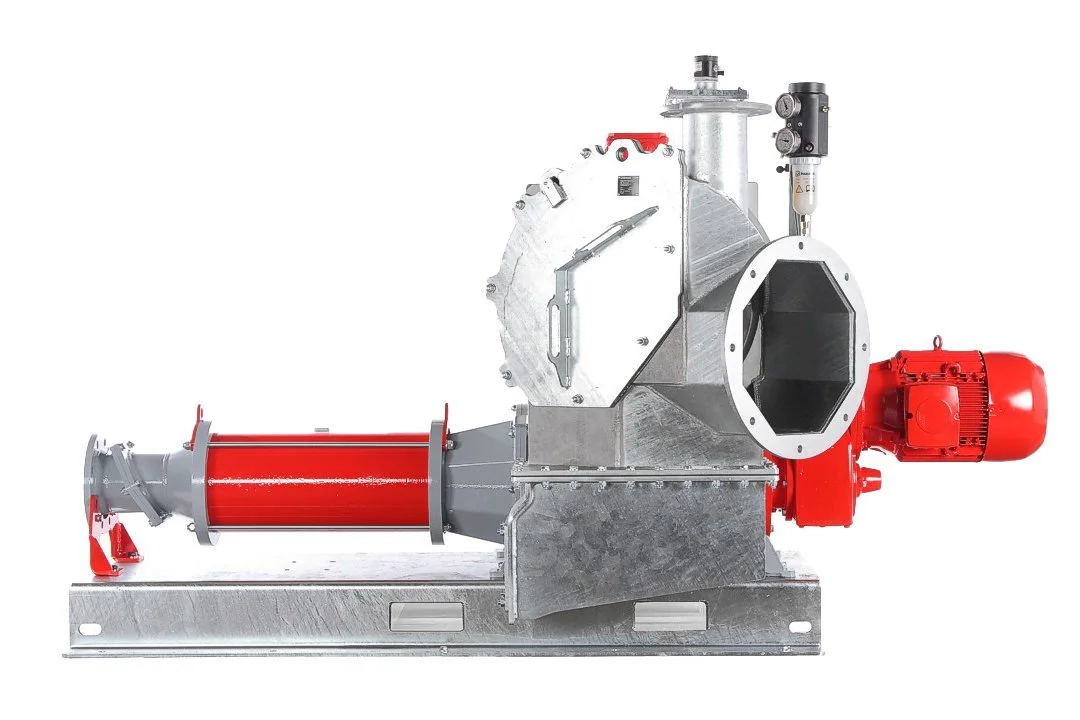

Reliable solid matter feeding is an essential prerequisite for efficient biogas production. That is why we have further developed our worldwide proven PreMix solid matter feeding system based on customer feedback from thousands of installations. Like the previous PreMix, the new generation combines four preparation steps in one compact, space-saving unit. A wide variety of substrates are processed into a homogeneous, bacteria-compatible suspension. As a completely closed system, the new generation of PreMix can now also be used in closed rooms.

Dynamic cutting performance control: The new generation features a new version of the ACCplus blade adjustment system. This not only adjusts the blades automatically, but also adapts the cutting performance of the RotaCut RCX independently and dynamically to the substrate.

Long-lasting & efficient pump: The HiCone progressive cavity pump, another element of the new PreMix, stands for multiplied service life and reduced energy requirements.

Increased automation for efficient solid matter feeding: The sophisticated control system of the new PreMix automatically regulates the system automatically within the optimum range to ensure efficient solid matter feeding.

Models of the PreMix

The compact and versatile solid matter feeder

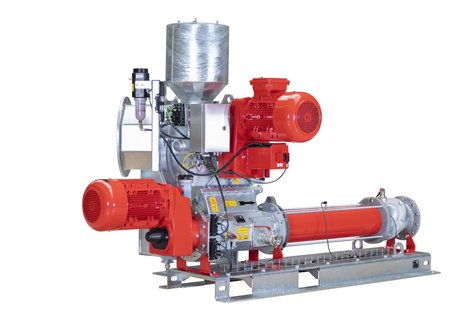

PreMix RCX-58G

The compact, standard model for variable solid matter feeding into typical biogas plants. When you need to feed a wide variety of biomass such as organic waste, dry chicken manure, grass silage, and food waste into the digester, this model is the right choice.

Downloads

The high performance solid matter feeder

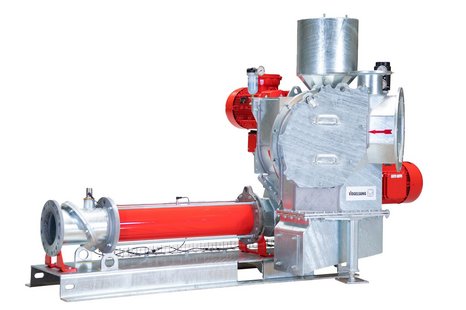

PreMix RCX-68G

The PreMix based on the RCX-68G guarantees optimum preparation and feeding of a wide variety of solid matter and substrates with maximum performance and effectiveness. This makes it particularly well suited for large biogas plants and everywhere where intensive preparation of the substrate or high material flow rates are required.

Downloads

The compact and versatile solid matter feeder

PreMix RCX-58G

The compact, standard model for variable solid matter feeding into typical biogas plants. When you need to feed a wide variety of biomass such as organic waste, dry chicken manure, grass silage, and food waste into the digester, this model is the right choice.

Downloads

The high performance solid matter feeder

PreMix RCX-68G

The PreMix based on the RCX-68G guarantees optimum preparation and feeding of a wide variety of solid matter and substrates with maximum performance and effectiveness. This makes it particularly well suited for large biogas plants and everywhere where intensive preparation of the substrate or high material flow rates are required.

Downloads

Features of the PreMix

Options of the PreMix

The universal 4-in-1 solid matter feeder for cost-effective digester feeding

The solid matter feeder PreMix for biogas applications

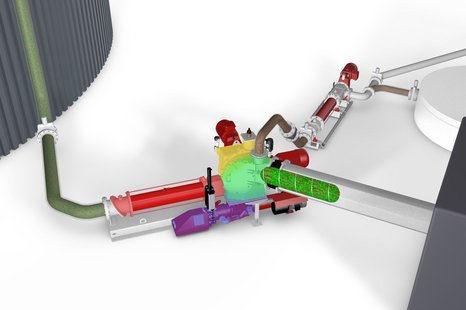

Mixing a variety of solids with a liquid and mashing it all to form a homogeneous organic suspension suitable for bacteria – that is the PreMix’s strength. This is why the solid matter feeder is just as suited for renewable resources as well as other input materials – whether that means pasty food waste, bulky crops or organic waste.

One decisive advantage of the solid matter feeder PreMix is its foreign matter separator and the preparation of the biomass, even before the integrated positive displacement pump: After the biomass has been fed to the solid matter feeder via a screw conveyor, the first step is to separate out the heavy material. Then, coarse particles are crushed and fibrous matter is cutted. Right from the start, this smart concept thus avoids damage from stones, metal parts and other heavy material and ensures that the biomass is properly prepared for the bacteria. One PreMix can supply several digesters. A drive power of 20 to 50 kW is sufficient (depending upon the model) for delivery rates from 20 to over 100 m3/h.

Due to its compact design, just a few square meters are enough to set up the PreMix – including space for service and maintenance work. This makes the installation and integration into new systems or the update of existing biogas plants easy, and operators can flexibly make use of the most varied biomass, without having to change the parameters for the solid matter feeder for every change. Combined with a Vogelsang Performance Cut Control (PCU), the solid matter feeder is ready to be automated.

Downloads