VX rotary lobe pump: Increased efficiency and halved loading times

Case study: ENTS Transport Limited

The customer and the problem

ENTS Transport in Ireland is a haulage company operating a fleet of 14 tankers providing transportation and courier services across Ireland. The company specialises in pumping highly viscous materials such as molasses, whey protein and pot ale syrup.

ENTS faced recurring issues with the pumps installed on their tankers. Pump shafts frequently broke, bearings required regular replacement and overall servicing needs were high. In addition, each tank took more than an hour to fill, causing significant delays in daily operations. These problems resulted in increased maintenance and material costs as well as long loading times.

The solution

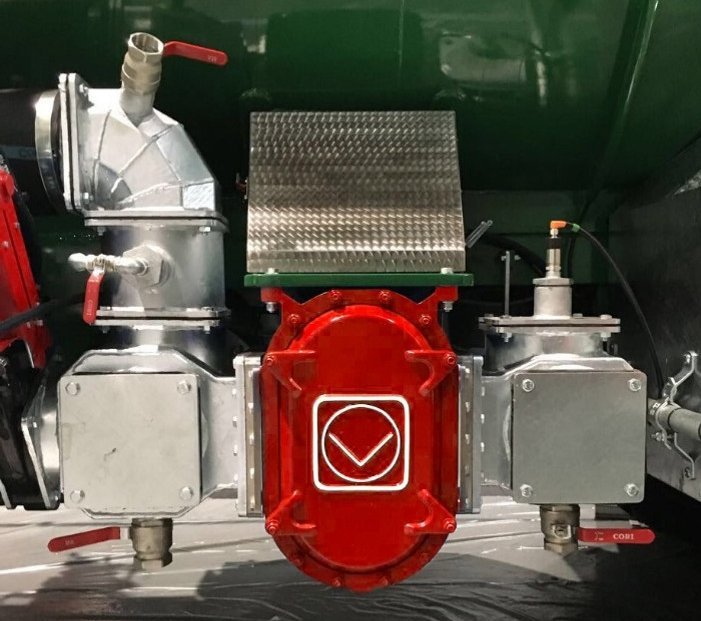

To address these challenges, ENTS replaced their existing pumps with Vogelsang VX136-140Q rotary lobe pumps. Handling highly viscous media, the pumps were fitted with Silicon Carbide (SiSiC) mechanical seals, while PUR lobes were used for whey applications. The compact design allowed for straightforward installation and quick servicing, cutting both material and maintenance costs.

Pumping performance rose to 54 m³/h, reducing loading time by 30 minutes per tank. The strengthened shaft design prevents breakages, lowering operational and spare parts costs. Fewer spare parts are needed overall, and the pumps now enjoy a significantly longer service life.

Since the first purchase in April 2014, ENTS has added 11 Vogelsang pumps to their expanding fleet—none of which have required servicing to date.