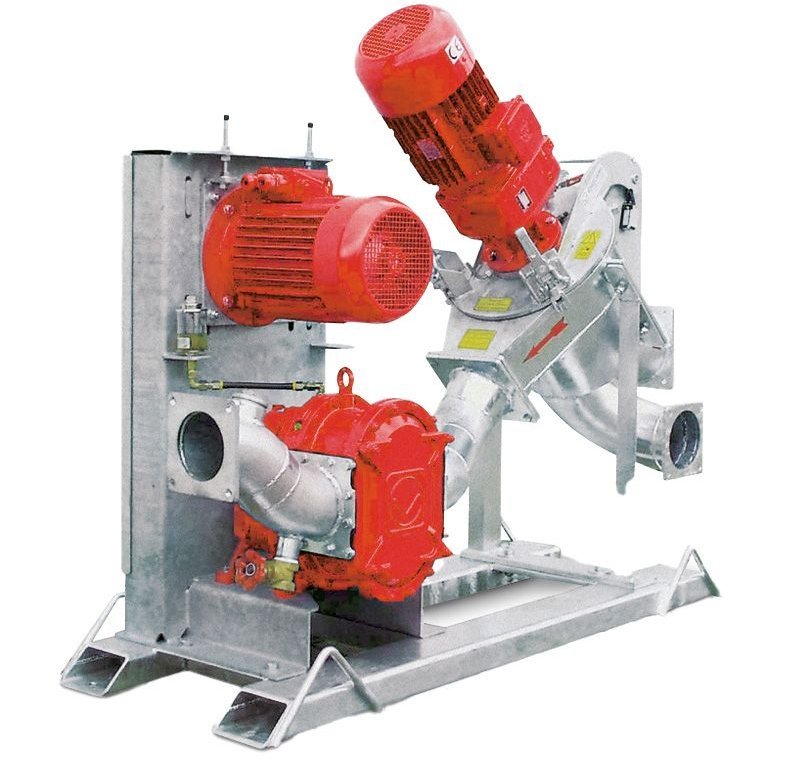

Rotary lobe pump and CC.Mix: solve the problem of varying dry matter contents

Case study: WWTP ATAL

Problem

Different sludges must be remixed, with very limited space in the basement.

Solution

The Vogelsang rotary lobe pump and CC-Mix solve the problem of varying dry matter content.

The customer and the problem

ATAL, based in Hong Kong, specializes in wastewater treatment, food waste treatment, and biogas production.

The Shatin sewage treatment plant is one of the largest municipal sewage treatment plants in Hong Kong. Shatin also uses dewatered sludge from various sewage treatment plants for biogas production.

The Shatin wastewater treatment plant also processes dewatered sludge from various wastewater treatment plants in Hong Kong for biogas production. These different sludges have different dry matter contents (28–45%) depending on the dewatering system. To optimize biogas production, these different sludges must be remixed (diluted CEPT sludge with 4–5% dry matter content). The sludge from the other wastewater treatment plants is transported by truck to the Shatin wastewater treatment plant. The bunker (storage tank) and the remixing plant must be installed in the basement, where space is limited.

The solution

To optimize the size and outlet of the sludge from the collection tank, the customer uses two conical outlets with two screw conveyors. Due to the limited space in the basement, the size and low space requirements, especially for service and maintenance, are significant advantages of the Vogelsang rotary lobe pump and the CC-Mix.

Two rotary lobe pumps VX136-210Q are used for the water supply for back mixing.Rotary lobe pumps from Vogelsang are self-priming and insensitive to dry running and foreign bodies, which leads to low wear and thus to high system availability. These properties are particularly important to the customer for problem-free handling of the back mixing application.

Advantages

- No pulsation

- Back mixing of dewatered sludge up to 45% DS - content

- Optimized performance

- Space saving

- Less repair- and downtime