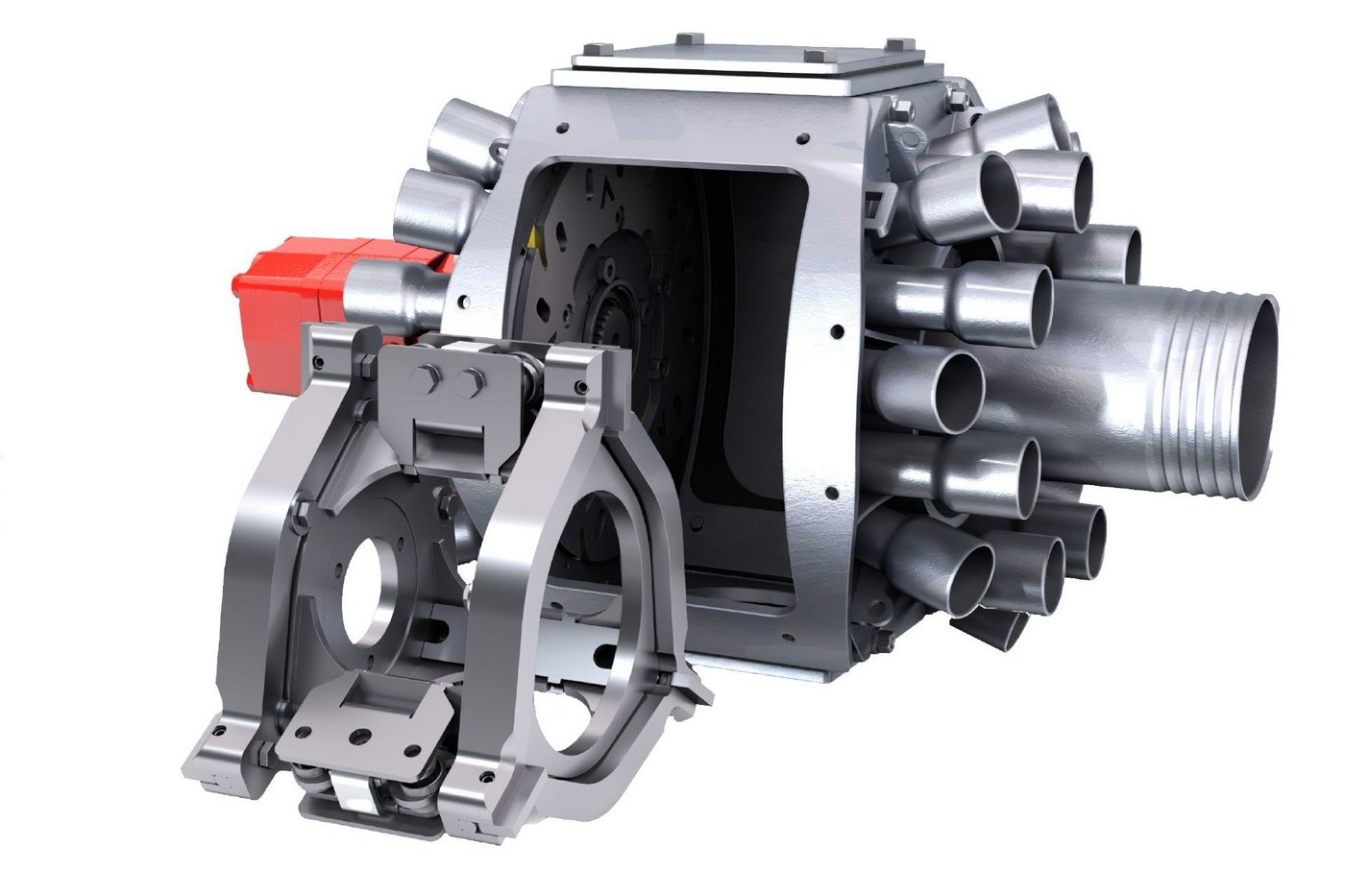

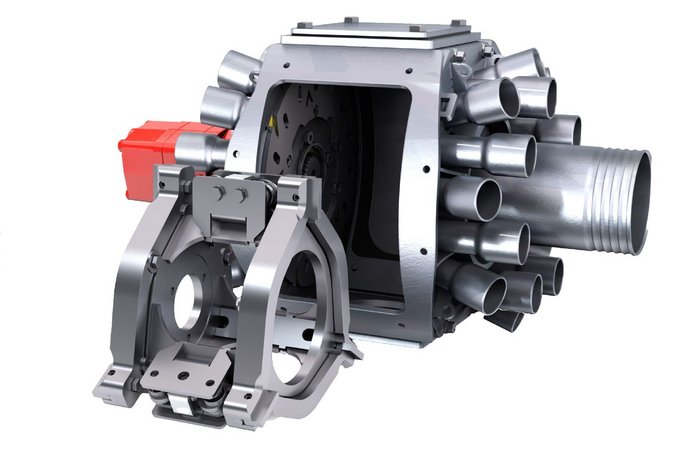

Slurry macerator without air suction

ExaCut ECC

- Innovative rotor design for precise slurry distribution without air suction or ventilation hoses

- Very quiet operation with smooth, pulsation-free hose flow

- QuickService maintenance concept allows easy rotor servicing without removing hoses

Runs easily without air

The powerful ExaCut ECC slurry macerator with innovative rotor technology

Until recently, all slurry macerators on the market relied on ventilation hoses and air suction to ensure even slurry flow into the discharge lines. Vogelsang is proud to be the first agricultural technology developer worldwide to create a slurry macerator that requires no air suction. The innovative rotor design of the new ExaCut ECC prevents negative pressure, delivering exceptionally smooth and even slurry feeding to the hose outlets for precise, consistent distribution.

Generous cross-sections ensure the ExaCut ECC runs smoothly while reducing power and oil consumption—benefits that farmers and contractors in Ireland will appreciate. It also retains Vogelsang’s trusted features, including self-sharpening blades and high cutting force, combined with the proven QuickService maintenance system. The rotor can be serviced in just 20 minutes without disconnecting a single hose, saving valuable time and effort during upkeep.