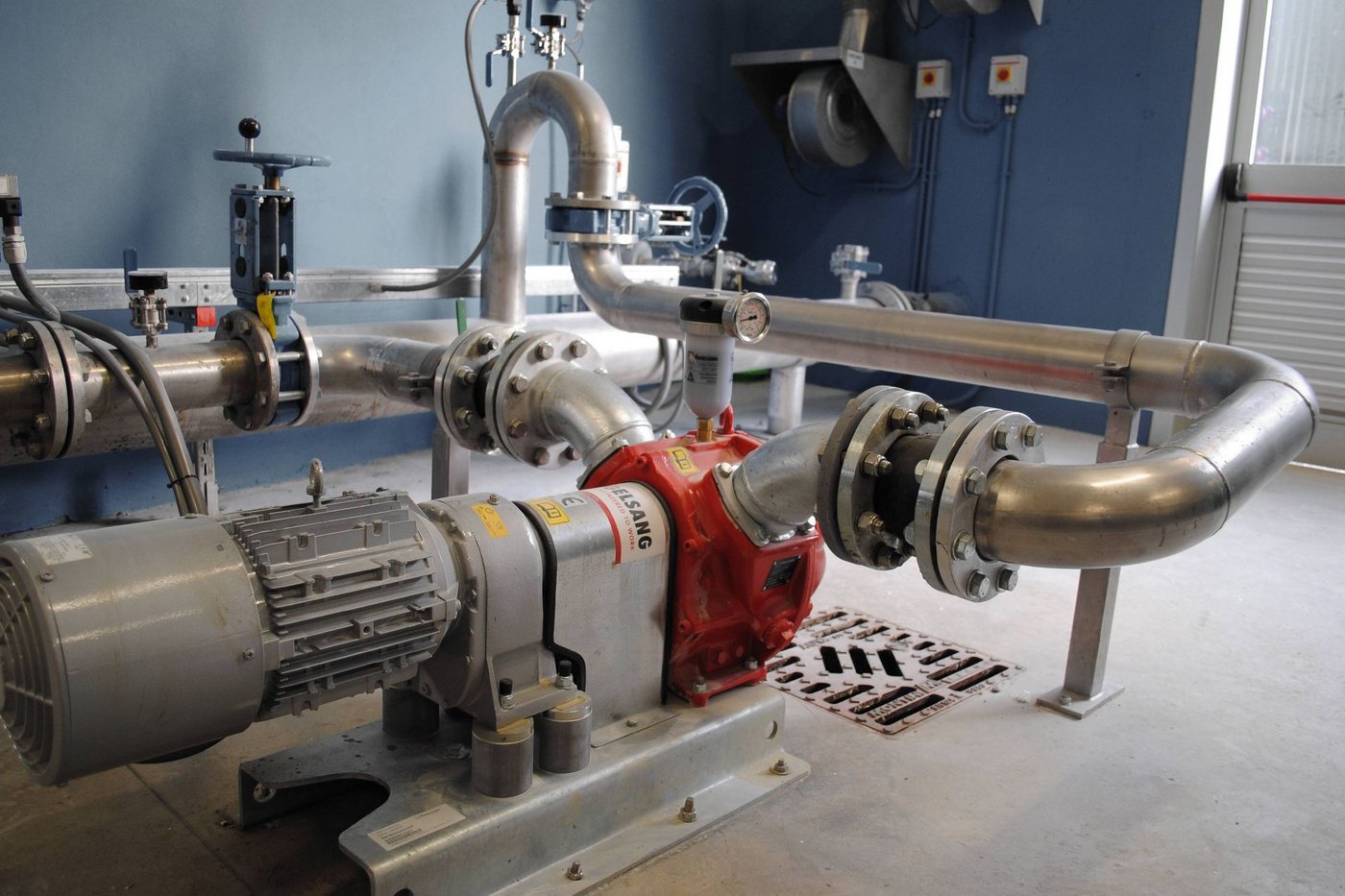

The rotary lobe pump is a true all-rounder

Vogelsang first invented the elastomer-coated rotary lobe pump – then perfected it

Vogelsang rotary lobe pumps are exceptionally easy to maintain, come in an impressive range of sizes and designs, have numerous equipment options and material variants, and offer various drive possibilities and installation options. All the models have two things in common: a compact design and easy maintenance. With four pump series and various models, with up to eight sizes per model, Vogelsang pump technology can be used for almost any application, delivery rate and pressure range. It will economically pump anything that flows.

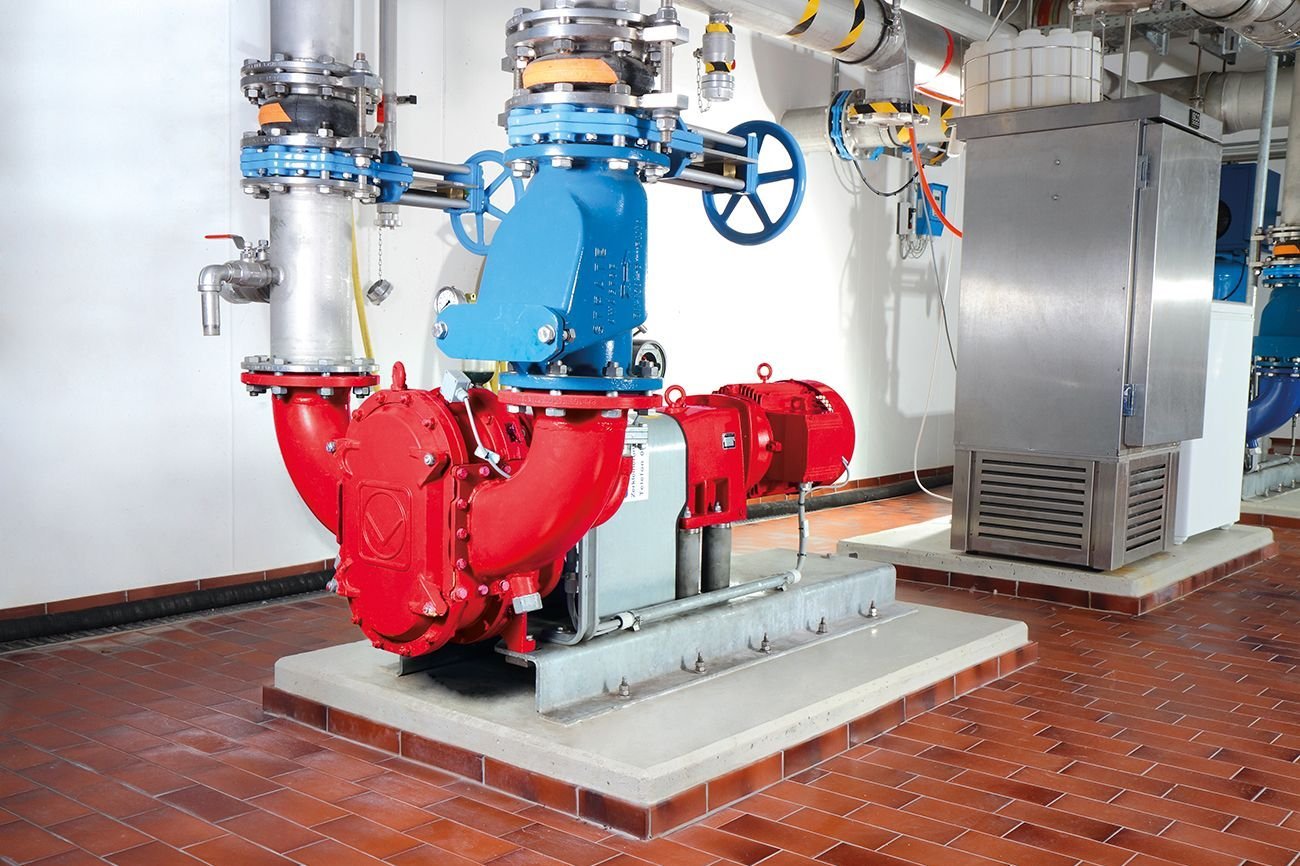

For maximum performance under extreme conditions

The EP series

- High differential pressures of up to 18 bar are possible

- Incomparable running smoothness due to high performance gearbox

- High efficiency thanks to the one-piece housing

- AirGap to protect the gearbox in the event of leakage

- Alternative seals per industry standards and customer requirements

- Quick connection for higher flange loads and easy maintenance

Proven liquid manure pump that offers you more

The FX series

- Comprehensive range of features and options

- Quick access to the pump chamber by removing the cover

- Simple service and maintenance

- Self-priming and dry-running resistant

- Shaft warranty

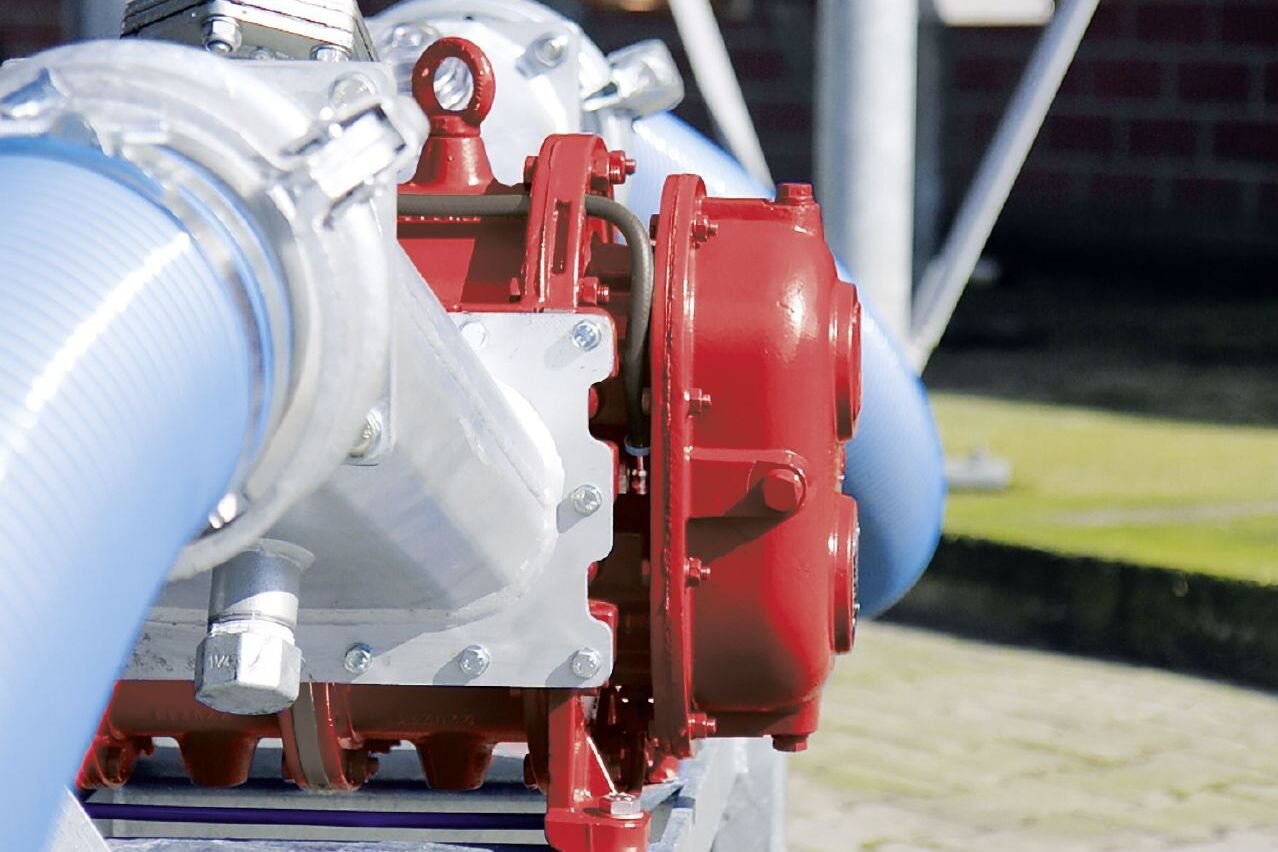

More compact and lightweight than ever before

The GL series

- Weight saving of up to 54 %

- Up to 151 kg weight saving compared to standard VX series models

- Up to 187 kg weight saving compared to similar models with hydraulic motors

- Space saving of approx. 35%

- Up to 28 cm shorter overall length compared to standard VX series models

- Lower power consumption

- Even more service-friendly

- Unmatched smooth running

Service and handling made even easier

The IQ series

- Quick and convenient access to pumping elements

- Intelligent, integrated foreign matter handling

- Excellent suction capacity and integrated dry running protection

- Significantly reduced spare parts costs

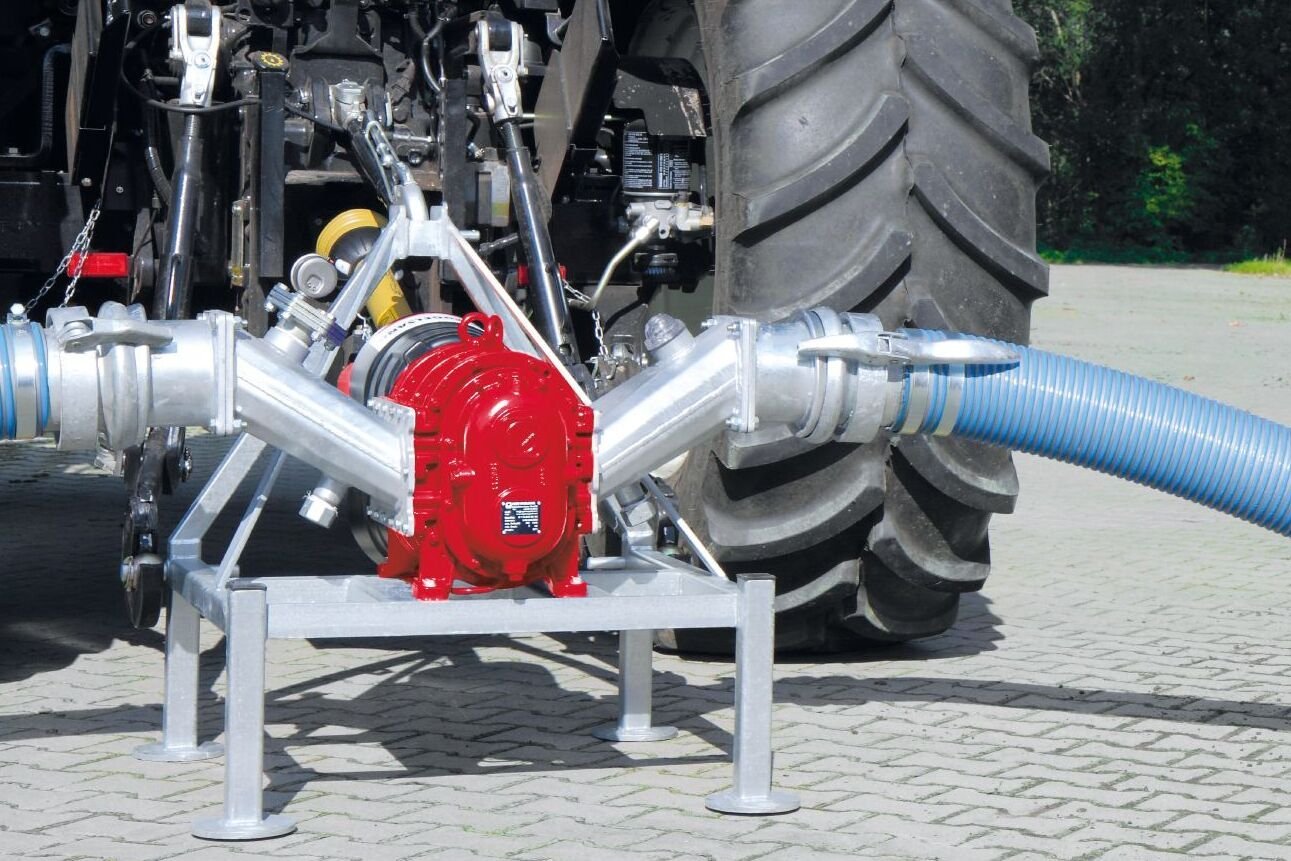

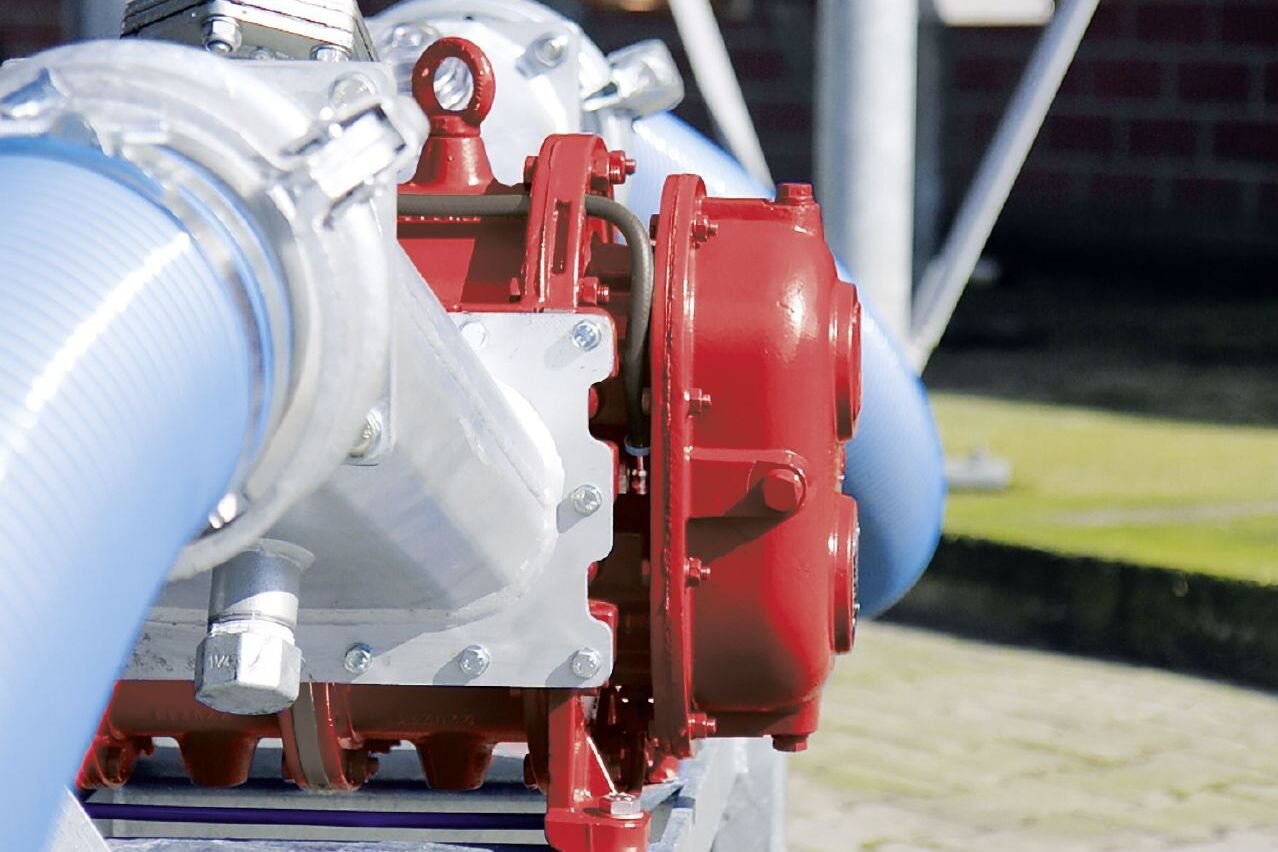

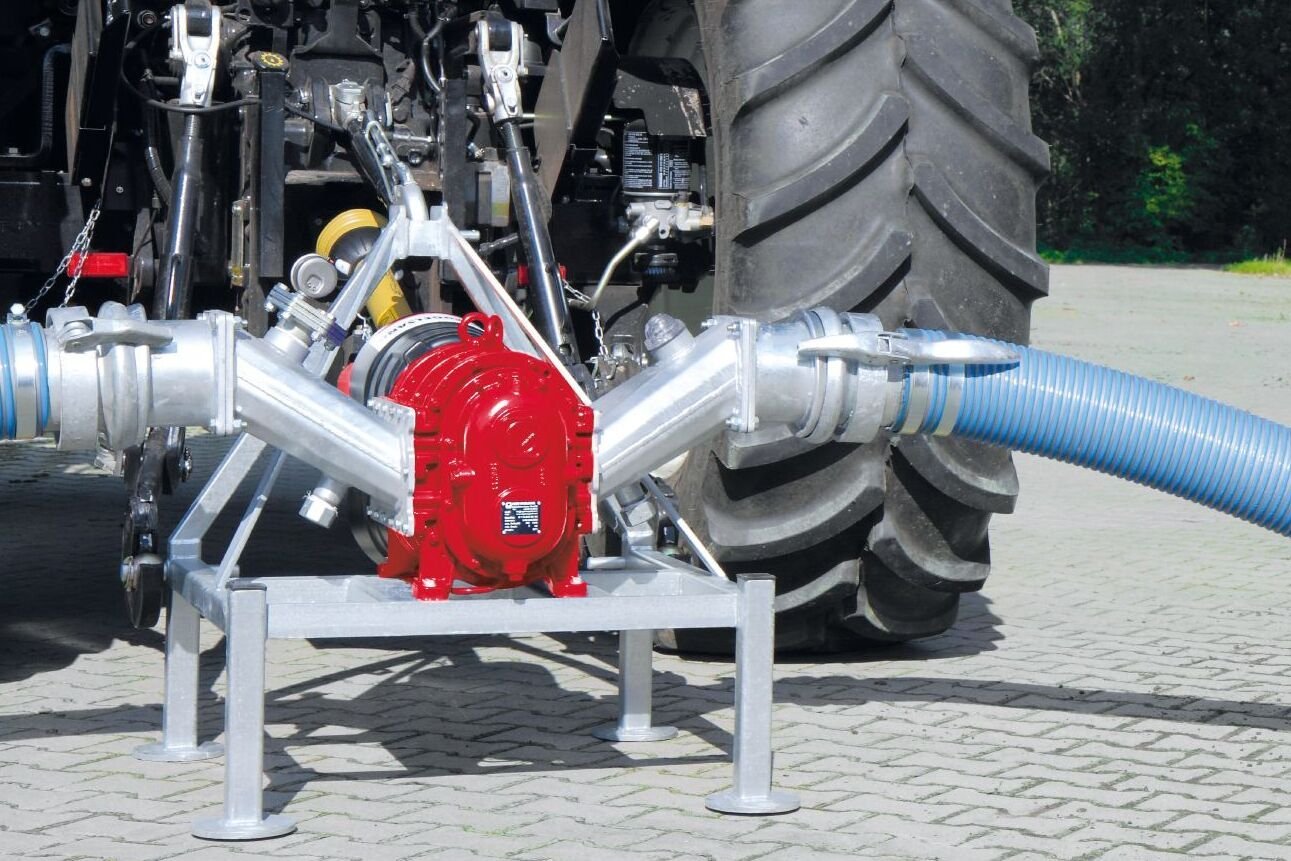

Thousandfold proven pump technology for yard and field

The R series

- Keep it simple: Economic solution with all necessary functions

- Ideal for both occasional and simultaneously reliable use

- Self-priming and resistant to foreign matter

- Smooth running thanks to sophisticated rotary lobe design

- Axial wear plates for maximum protection of the pump chamber

- Flexible use thanks to different drive types

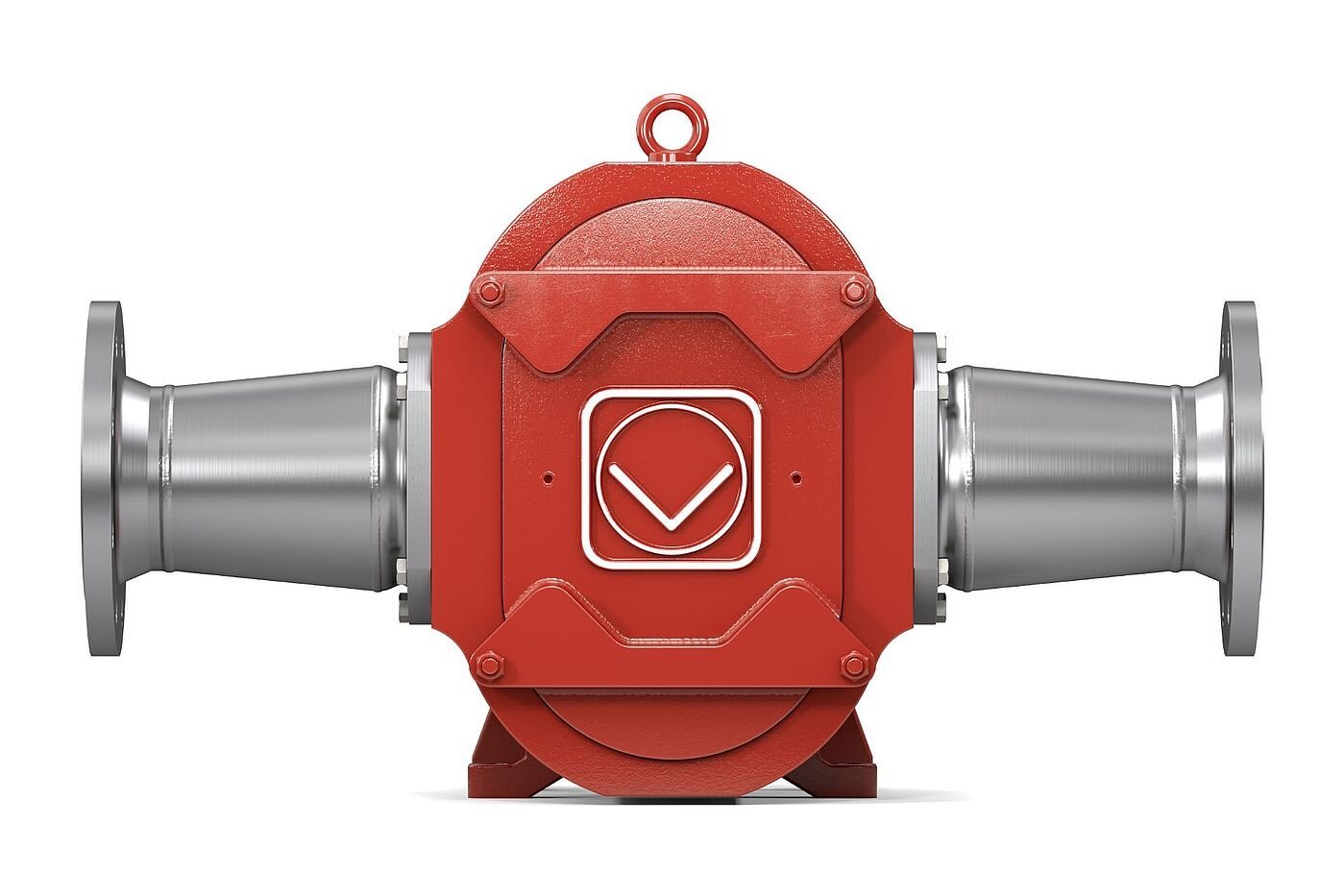

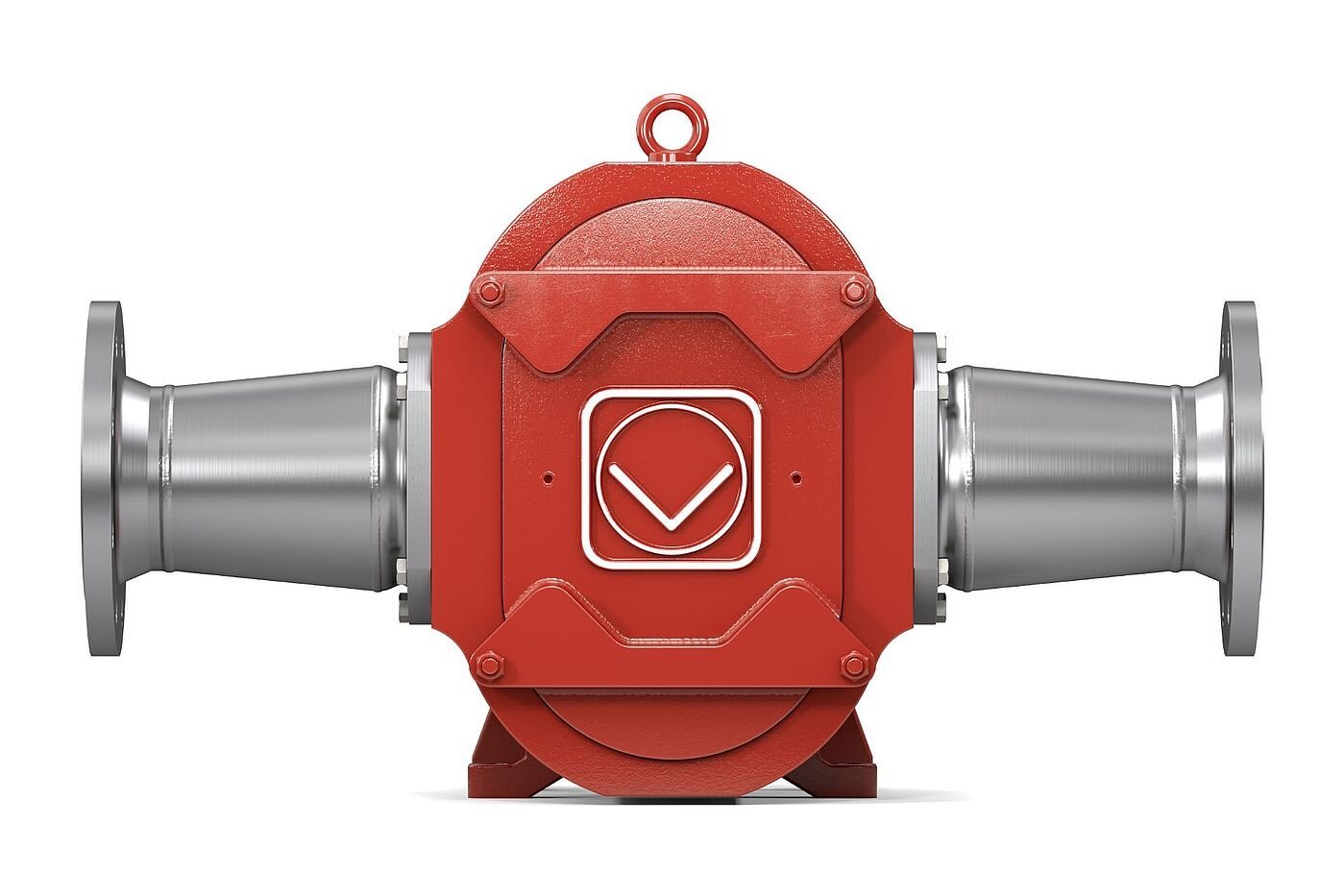

The adaptable rotary lobe pump for task-oriented pumping

The VX series

- Comprehensive range of features and options

- Quick access to the pump chamber by removing the cover

- Simple service and maintenance

- Self-priming and dry-running resistant

- Shaft warranty

The new design for any situation

The VY series

- Keep it simple: Economic solution with all necessary functions

- Ideal for both occasional and simultaneously reliable use

- Self-priming and resistant to foreign matter

- Smooth running thanks to sophisticated rotary lobe design

- Axial wear plates for maximum protection of the pump chamber

- Flexible use thanks to different drive types

Rugged, yet sensitive pumps for minimal technical impact on the grape

The wine pump

- Gently moves grapes and wine without shaking and creating foam

- Reduced oxygenation of wine to maintain flavors intact

- Self-priming and able to operate under dry conditions

- Portable and stationary options

- Pulsation-free during operation

- Space-saving, flexible use

- Quick access to pump compartment by removing cover

- On-site assistance and maintenance

For maximum performance under extreme conditions

The EP series

- High differential pressures of up to 18 bar are possible

- Incomparable running smoothness due to high performance gearbox

- High efficiency thanks to the one-piece housing

- AirGap to protect the gearbox in the event of leakage

- Alternative seals per industry standards and customer requirements

- Quick connection for higher flange loads and easy maintenance

Proven liquid manure pump that offers you more

The FX series

- Comprehensive range of features and options

- Quick access to the pump chamber by removing the cover

- Simple service and maintenance

- Self-priming and dry-running resistant

- Shaft warranty

More compact and lightweight than ever before

The GL series

- Weight saving of up to 54 %

- Up to 151 kg weight saving compared to standard VX series models

- Up to 187 kg weight saving compared to similar models with hydraulic motors

- Space saving of approx. 35%

- Up to 28 cm shorter overall length compared to standard VX series models

- Lower power consumption

- Even more service-friendly

- Unmatched smooth running

Service and handling made even easier

The IQ series

- Quick and convenient access to pumping elements

- Intelligent, integrated foreign matter handling

- Excellent suction capacity and integrated dry running protection

- Significantly reduced spare parts costs

Thousandfold proven pump technology for yard and field

The R series

- Keep it simple: Economic solution with all necessary functions

- Ideal for both occasional and simultaneously reliable use

- Self-priming and resistant to foreign matter

- Smooth running thanks to sophisticated rotary lobe design

- Axial wear plates for maximum protection of the pump chamber

- Flexible use thanks to different drive types

The adaptable rotary lobe pump for task-oriented pumping

The VX series

- Comprehensive range of features and options

- Quick access to the pump chamber by removing the cover

- Simple service and maintenance

- Self-priming and dry-running resistant

- Shaft warranty

The new design for any situation

The VY series

- Keep it simple: Economic solution with all necessary functions

- Ideal for both occasional and simultaneously reliable use

- Self-priming and resistant to foreign matter

- Smooth running thanks to sophisticated rotary lobe design

- Axial wear plates for maximum protection of the pump chamber

- Flexible use thanks to different drive types

Rugged, yet sensitive pumps for minimal technical impact on the grape

The wine pump

- Gently moves grapes and wine without shaking and creating foam

- Reduced oxygenation of wine to maintain flavors intact

- Self-priming and able to operate under dry conditions

- Portable and stationary options

- Pulsation-free during operation

- Space-saving, flexible use

- Quick access to pump compartment by removing cover

- On-site assistance and maintenance