The universal pump system

BioCut

- Cost-effective pumping thanks to optimally coordinated components

- Reliable conveying of a wide range of challenging media

- Separation of heavy material and treatment of disruptive matter before the pump

- Compact design and minimal space requirements

- Service and maintenance can be performed quickly and easily on site

Effective combination

Developed specially for biogas plants

In most biogas plants, it’s necessary to prime, pump and prepare highly diverse liquid media. They usually contain a great deal of solids and fibrous matter, as well as disruptive matter like branches, hoof clumps, etc. – that are highly viscous and loaded with many foreign matter. Vogelsang has developed the compact pump system Bio-Cut especially for these kinds of demanding pumping tasks. It comprises a a robust positive

displacement pump with a powerful upstream cutter.

Models of the BioCut

The small pump system

BioCut VX136-105Q/RCQ-26G

The smallest pump system BioCut is the ideal choice for treating and pumping small volume flows of media containing foreign matter and disruptive matter. The upstream wet grinder RotaCut cuts fibrous solid matter and reliably separates out heavy material.

Downloads

The small and powerful pump system

BioCut VX136-105Q/RCQ-33Gpro

The small BioCut with the powerful RCQpro RotaCut was designed specifically to efficiently and reliably treat and pump small quantities of challenging media. Even if there is a high solids content, this unit can turn a heterogeneous medium into a homogeneous suspension.

Downloads

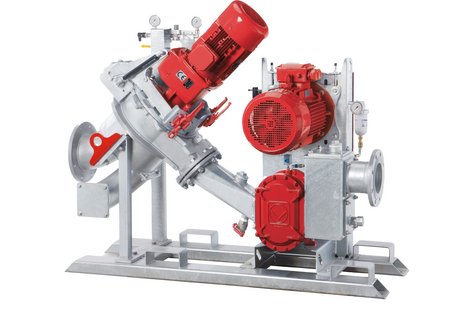

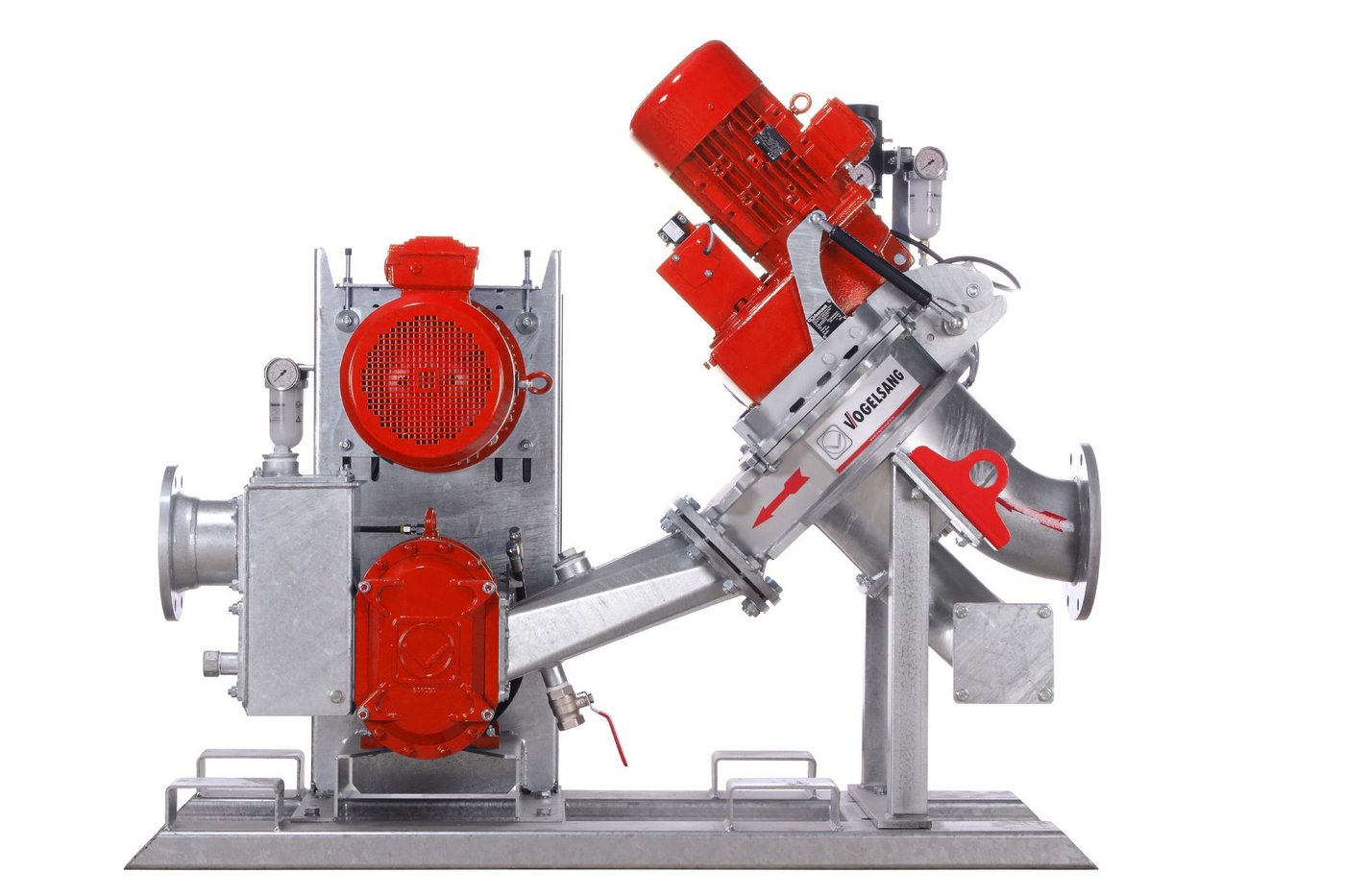

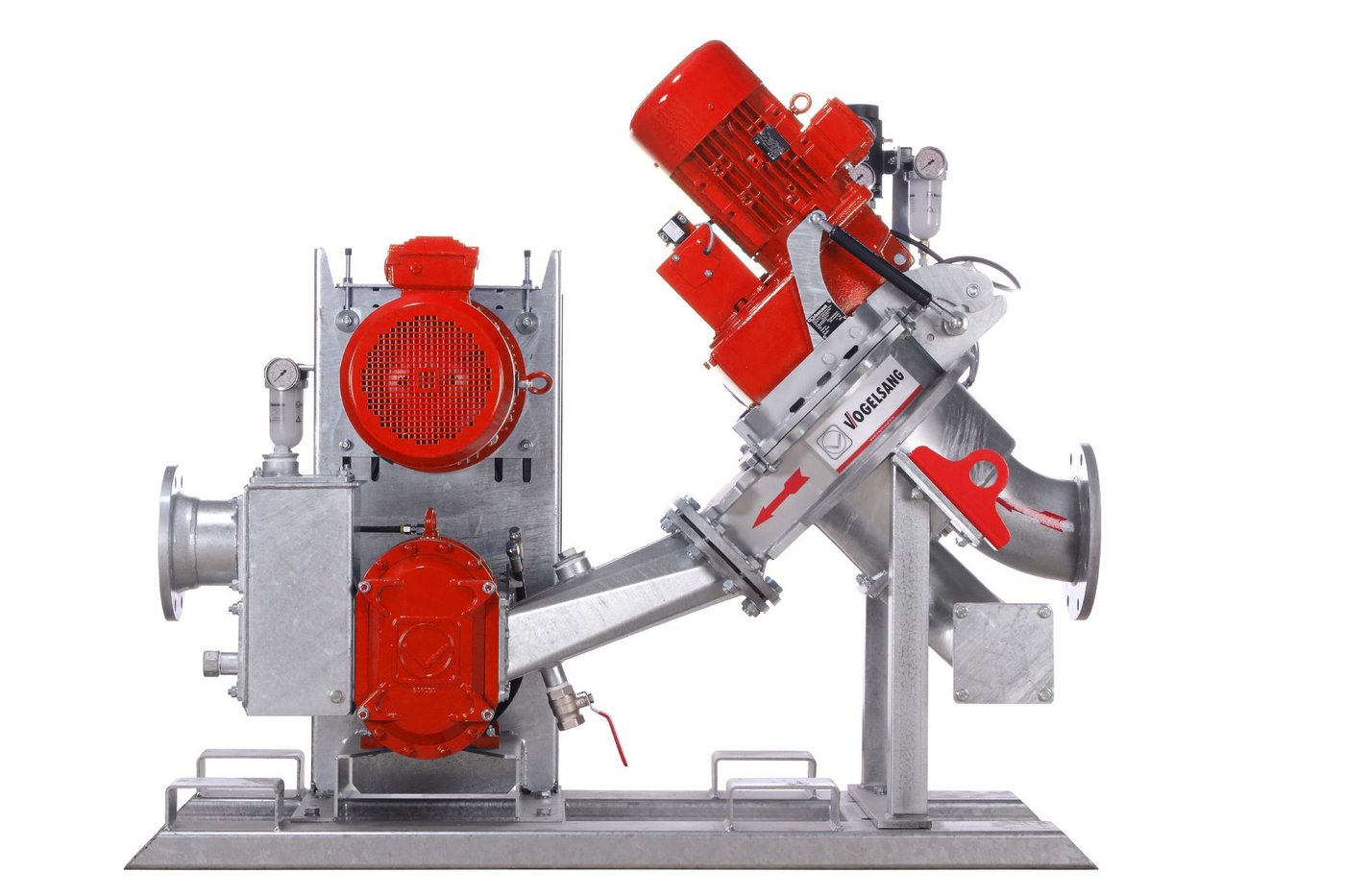

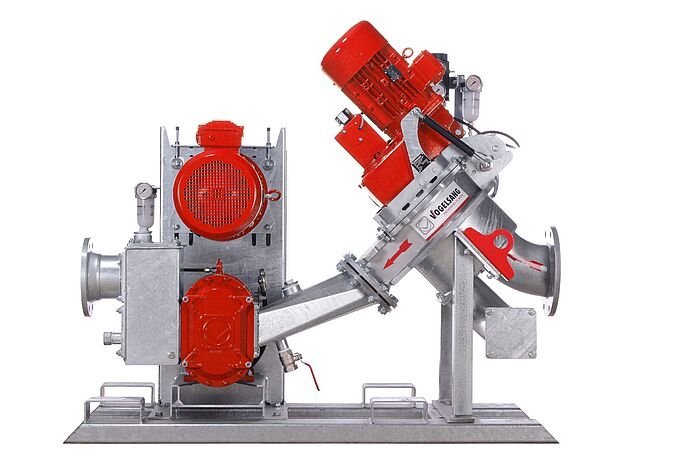

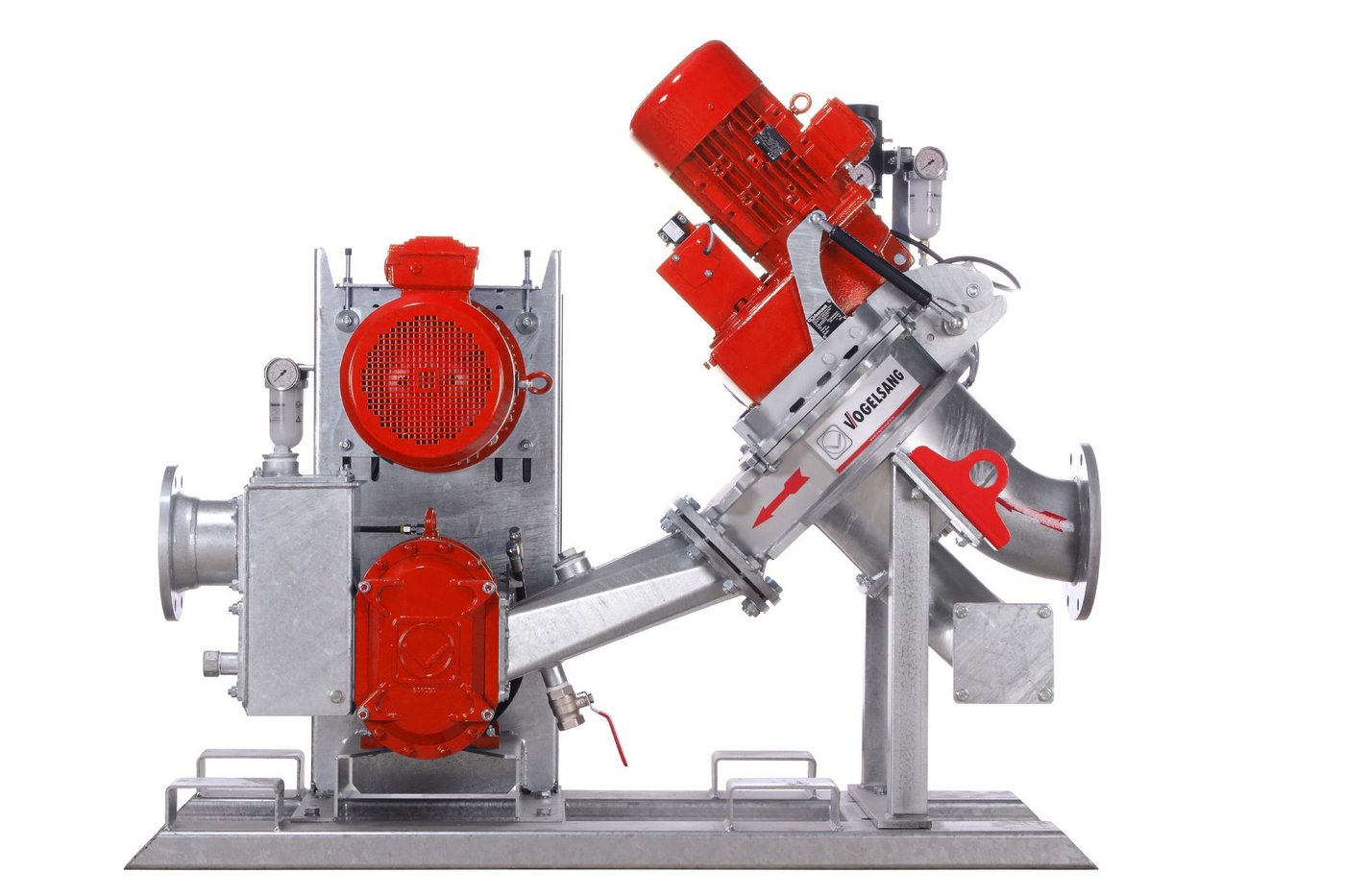

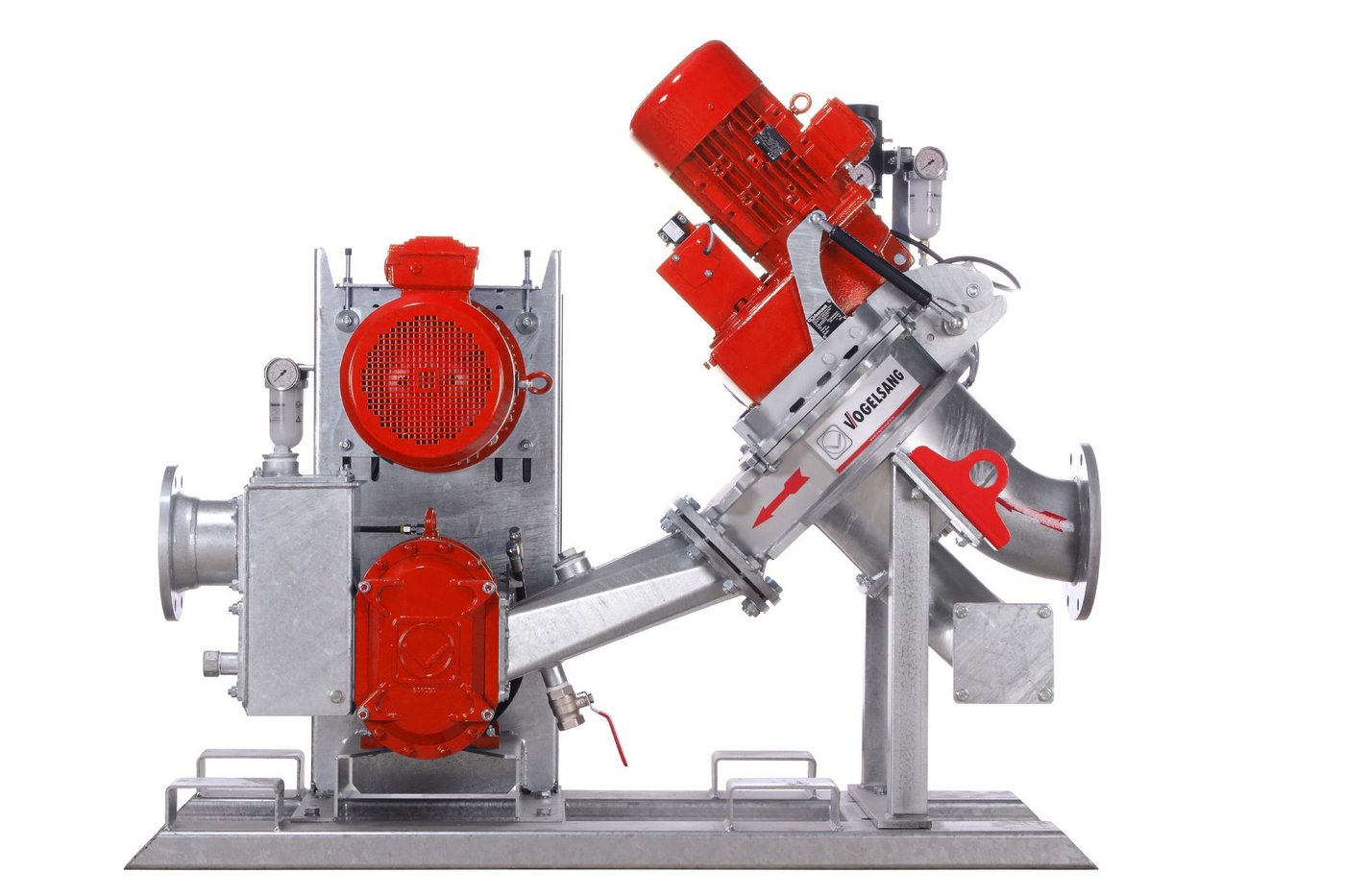

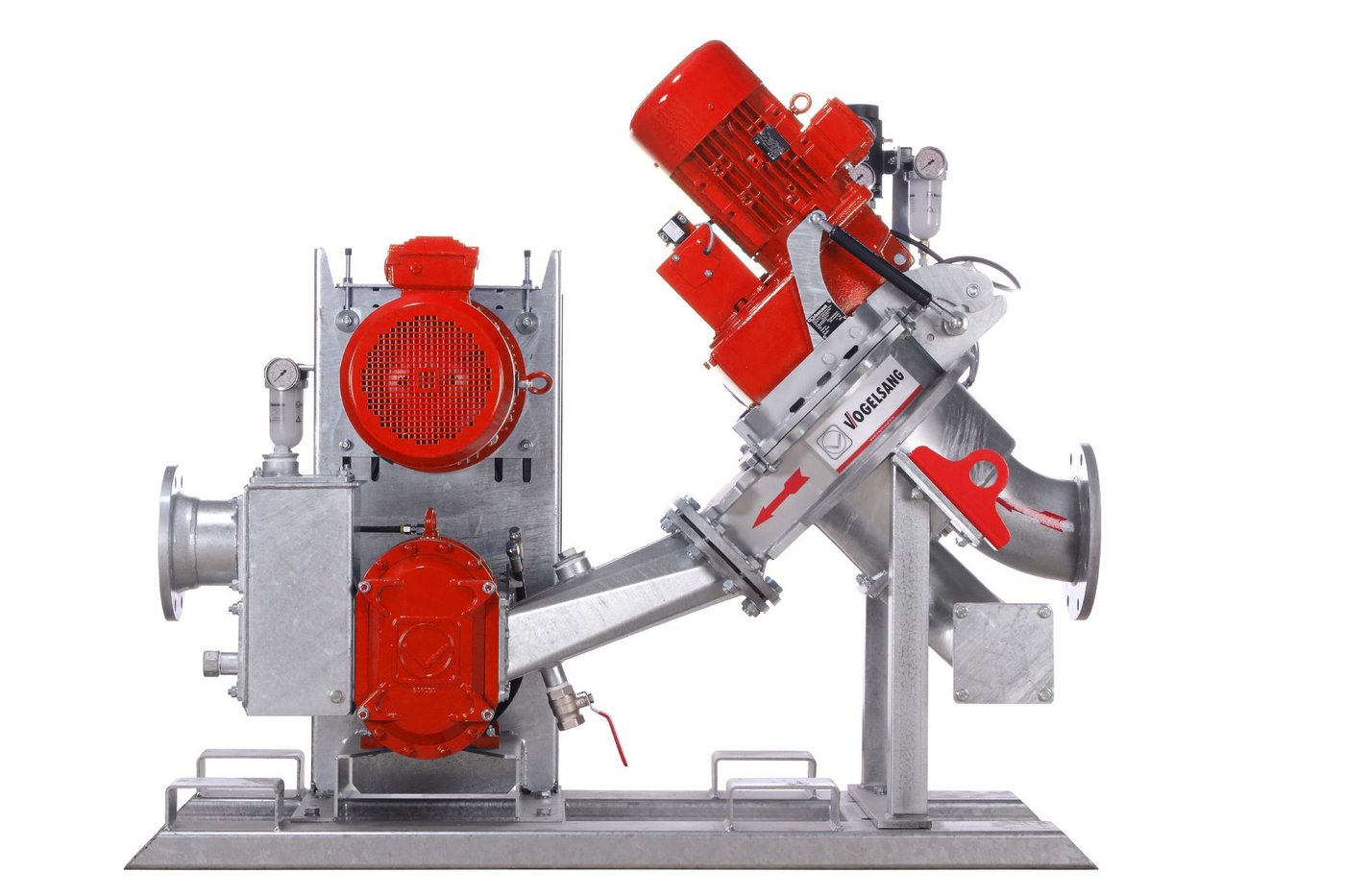

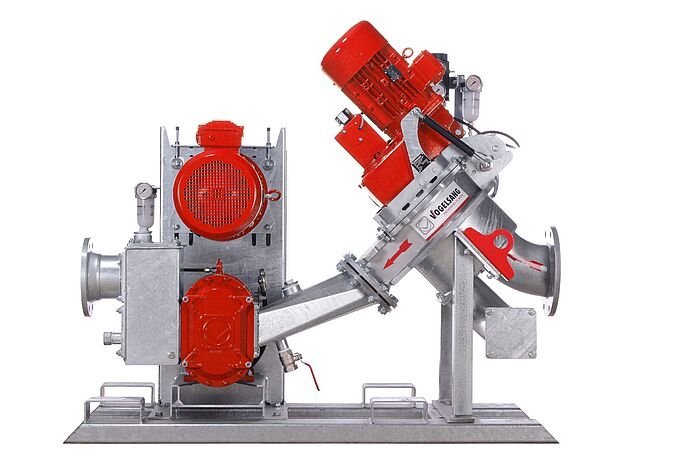

The universal standard pump system

BioCut VX136-140Q/RCQ-33Gpro

Our robust standard BioCut can be used for many conventional applications where media containing foreign matter and disruptive matter need to be treated and pumped. The BioCut reliably cuts and separates matter that could impair operation.

Downloads

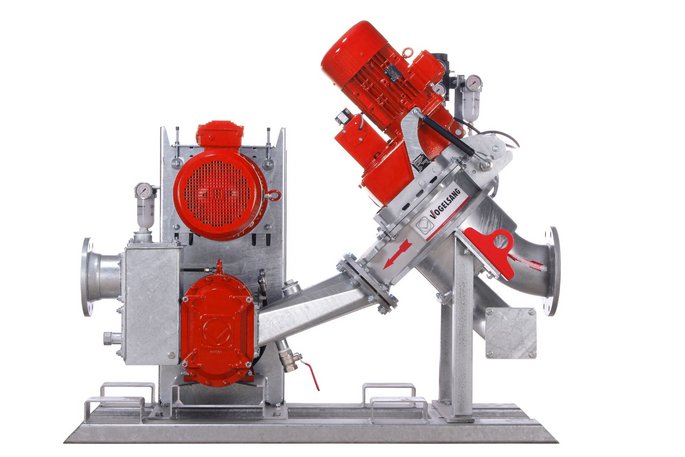

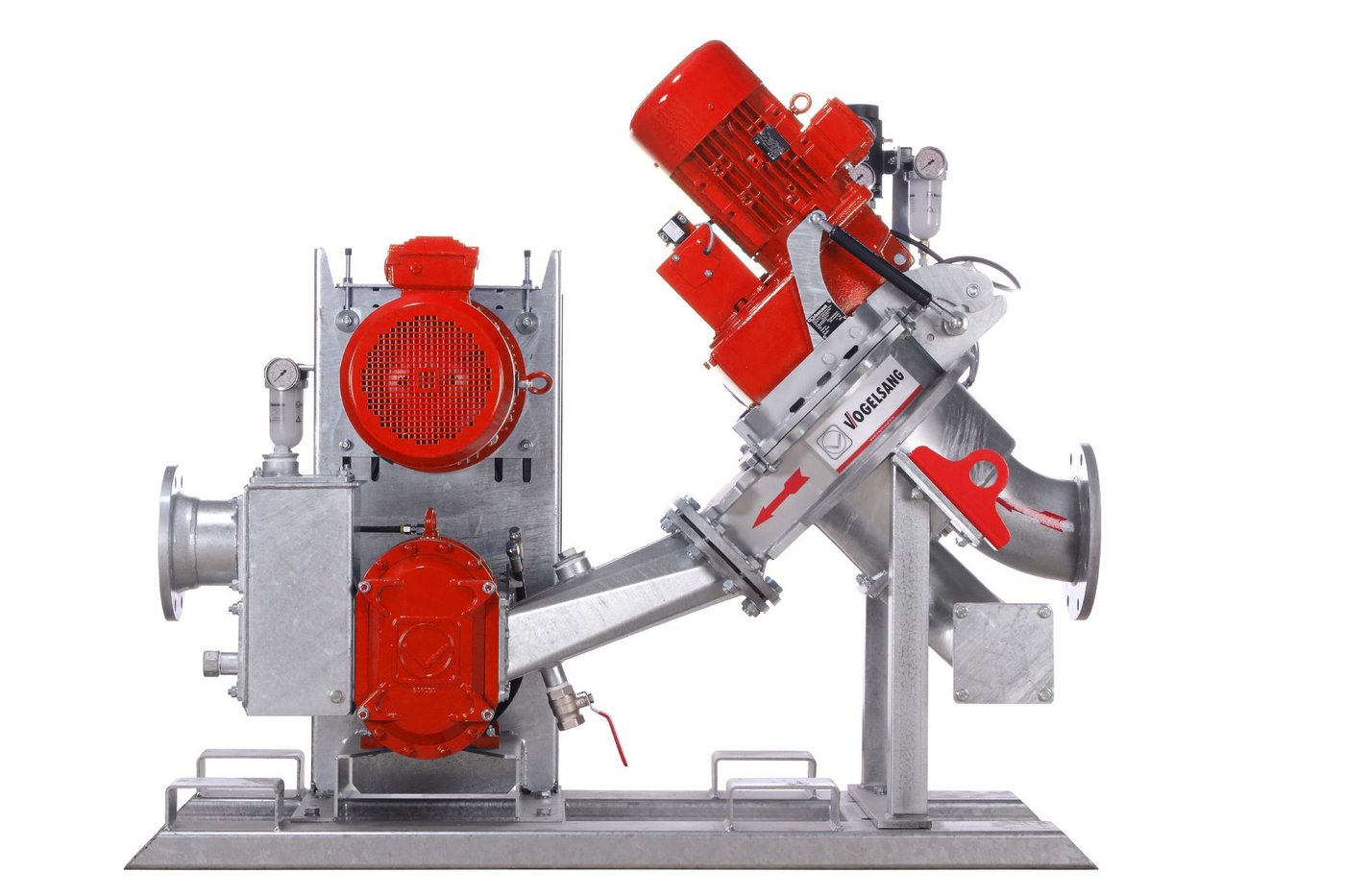

The large and effective pump system

BioCut VX186-130Q/RCQ-43Gpro

This BioCut is the efficient solution for treating and pumping large volume flows of viscous suspensions and media. And, at the same time, it reliably separates out heavy material and cuts disruptive or solid matter.

Downloads

The small pump system

BioCut VX136-105Q/RCQ-26G

The smallest pump system BioCut is the ideal choice for treating and pumping small volume flows of media containing foreign matter and disruptive matter. The upstream wet grinder RotaCut cuts fibrous solid matter and reliably separates out heavy material.

Downloads

The small and powerful pump system

BioCut VX136-105Q/RCQ-33Gpro

The small BioCut with the powerful RCQpro RotaCut was designed specifically to efficiently and reliably treat and pump small quantities of challenging media. Even if there is a high solids content, this unit can turn a heterogeneous medium into a homogeneous suspension.

Downloads

The universal standard pump system

BioCut VX136-140Q/RCQ-33Gpro

Our robust standard BioCut can be used for many conventional applications where media containing foreign matter and disruptive matter need to be treated and pumped. The BioCut reliably cuts and separates matter that could impair operation.

Downloads

The large and effective pump system

BioCut VX186-130Q/RCQ-43Gpro

This BioCut is the efficient solution for treating and pumping large volume flows of viscous suspensions and media. And, at the same time, it reliably separates out heavy material and cuts disruptive or solid matter.

Downloads

Features of the BioCut

Options of the BioCut

The universal and flexible pump system for biogas plants

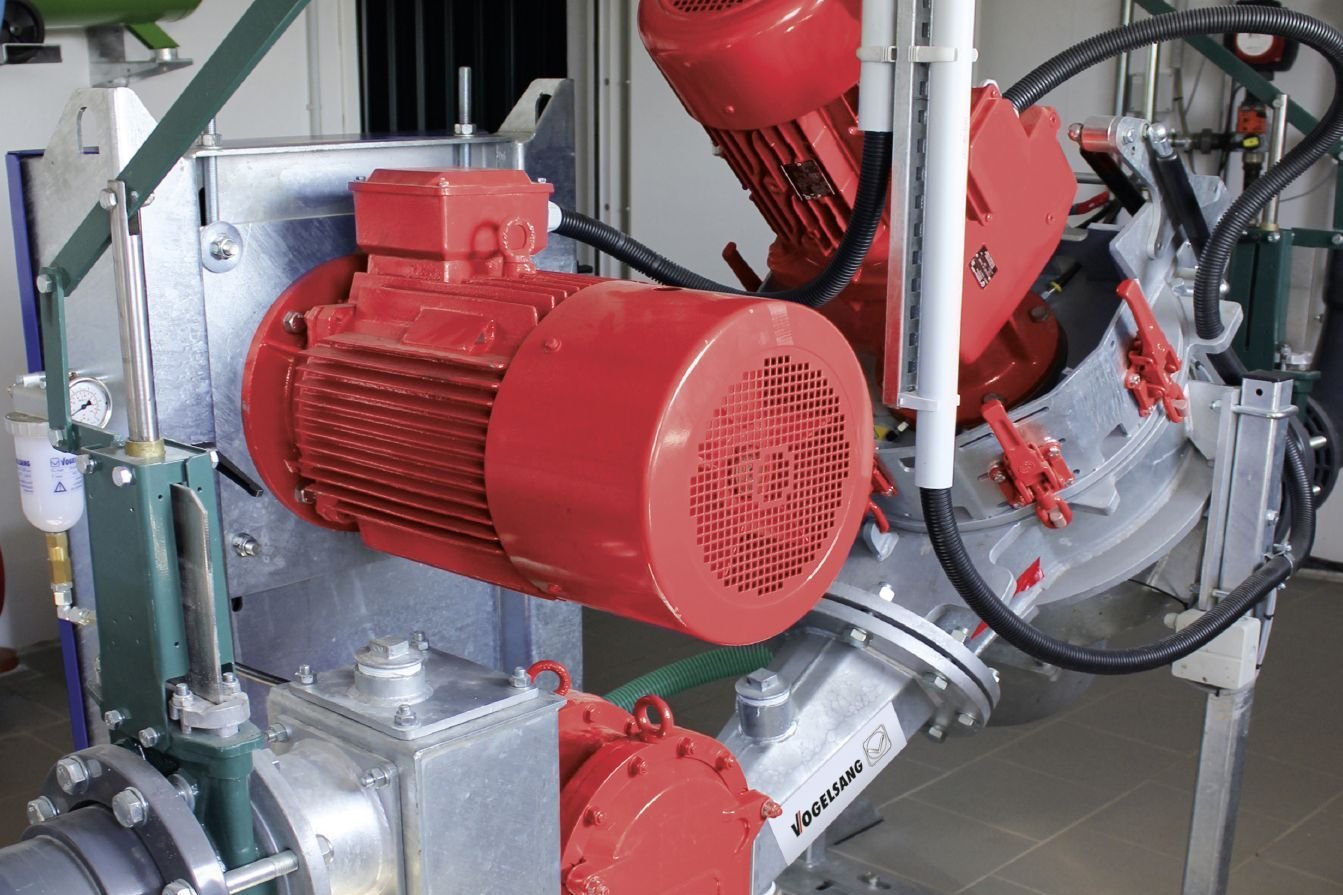

Pump system BioCut for biogas applications

In biogas plants, many different kinds of liquid media need to be conveyed, possibly after first being extracted from pits and treated. These media generally contain a high proportion of solid matter and fibrous components, as well as disruptive matter such as branches, chunks of hooves etc., and they are normally viscous and laden with foreign matter. These properties and characteristics are problematic for pumping, they lead to damage and malfunctions, and they have a negative impact on the efficiency of the biogas plant.

The BioCut was developed specifically to master challenging pumping tasks. The pump system combines a rotary lobe pump from the VX series and a RotaCut in a special type of construction that makes the overall unit extremely compact in its dimensions. Taking up minimal space, the BioCut acts as the central pump system, ensuring that heavy material like stones and metal parts are reliably separated out of the liquid manure, organic suspension or other fluids. At the same time, the BioCut shreds any disruptive matter in the fluid, such as biomass, and homogenizes the medium, which can then be pumped without difficulty. In addition, this thorough treatment reduces the tendency to form a floating layers and it lowers the viscosity. Indirectly, this results in lower power consumption of the plant, and the improved treatment has a positive effect on the gas yield.

And the system retains the full range of QuickService functions familiar from the VX rotary lobe pumps and the RotaCut: All wear parts can be replaced on site without dismounting the components.

Downloads