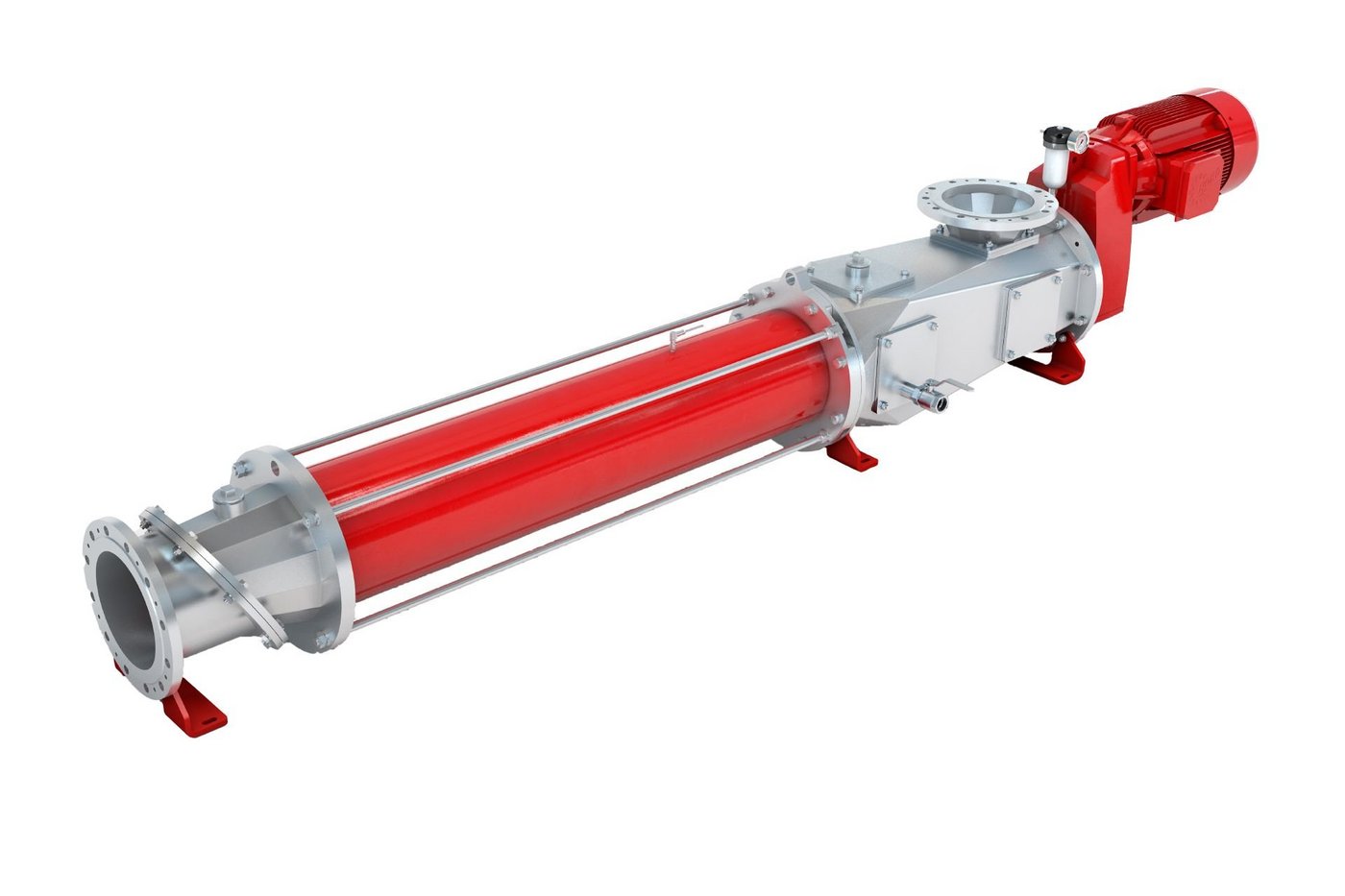

The progressive cavity pump with quick and easy service

CC series

- Easy and quick to service with minimal space requirements

- No disassembly of the discharge-side and suction-side pipes necessary

- Variety of options for changing parts

- The Quality Cartridge mechanical seal can be changed without opening the pump

- Sturdy cardan shaft with protective sleeve

Reliable pumping and simple parts replacement

Proven for media of all kinds and quick to maintain

Vogelsang’s CC series (CavityComfort) comprises rotating, positive displacement pumps that have proven themselves especially in challenging applications. The robust progressive cavity pumps demonstrate their durability and reliable pumping performance in applications involving highly viscous and abrasive media that may also have a high content of foreign matter. Thanks to the innovative design, CC-series pumps are ideal when long periods of downtime for service and maintenance are simply unacceptable.

Models of the CC series

The small, easy to maintain progressive cavity pump

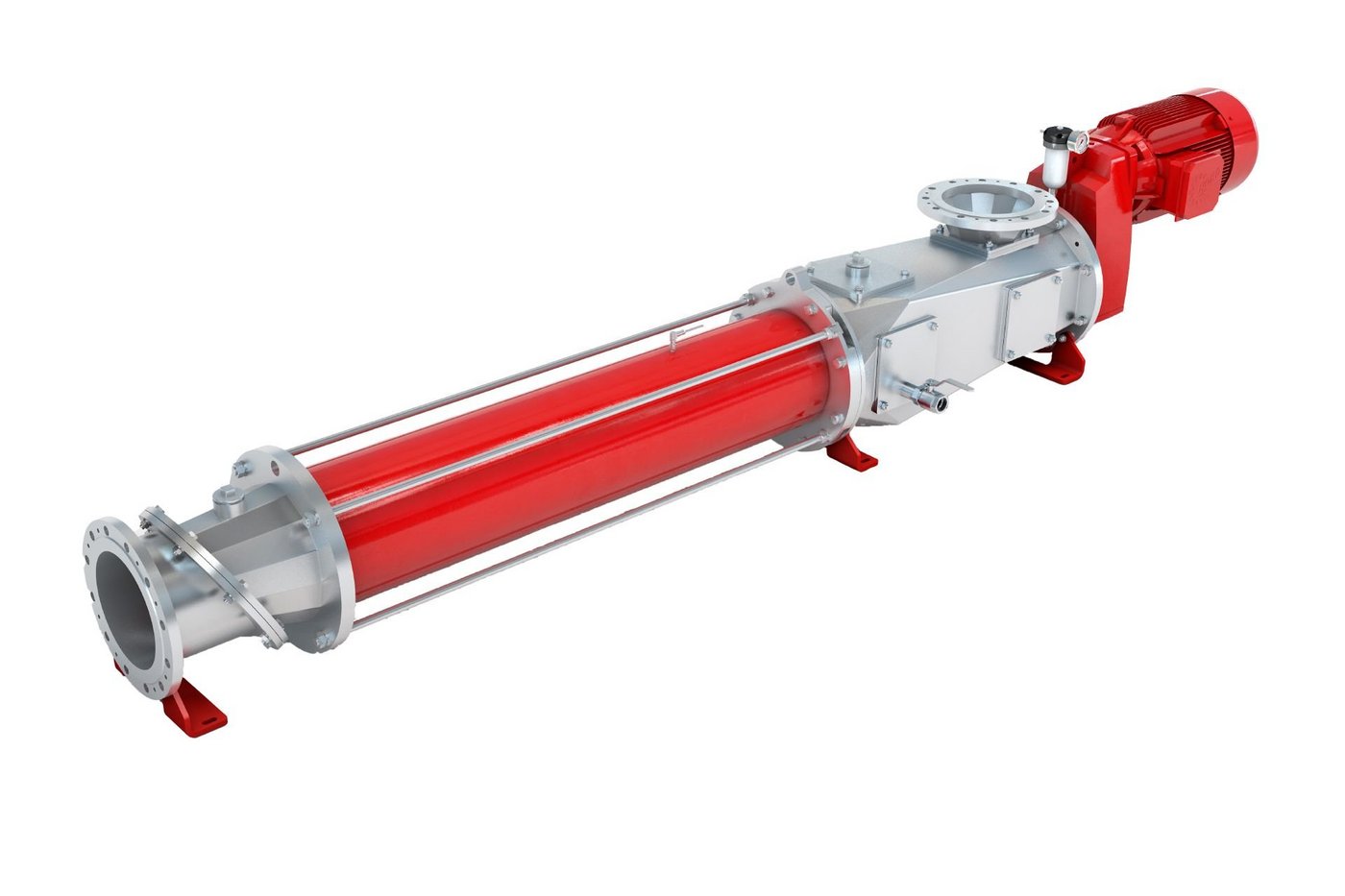

CC44

The CC44 is the Vogelsang progressive cavity pump for small capacities paired with the unique advantages of the Cavity Comfort CC series. Highly viscous sludge, abrasive organic suspension or sewage is pumped efficiently. Thanks to the large free passage, it is not sensitive to foreign matter and disruptive matter. At the same time, it features the easy and quick service typical of the CC series.

Downloads

The compact, easy to maintain progressive cavity pump

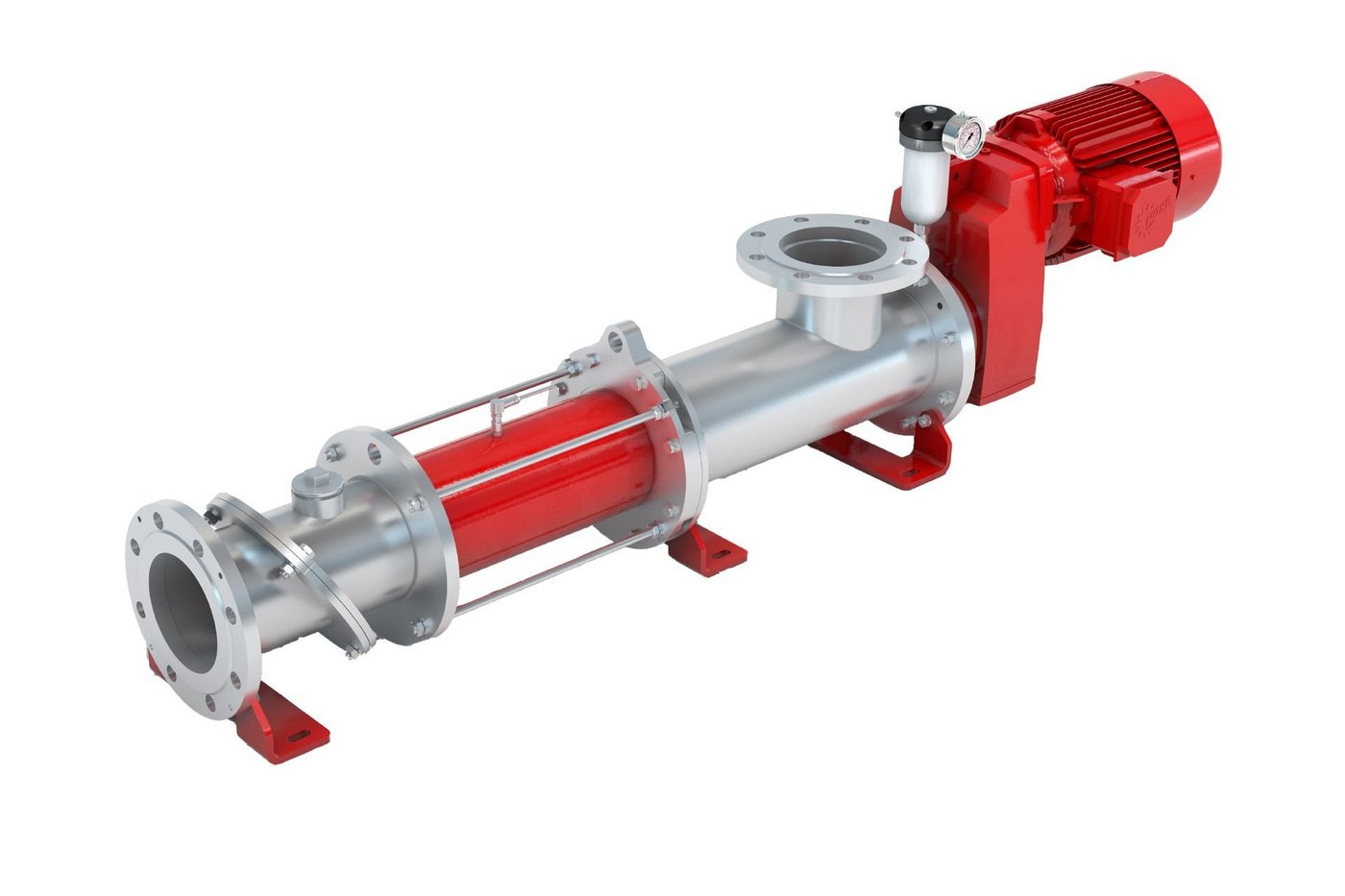

CC55

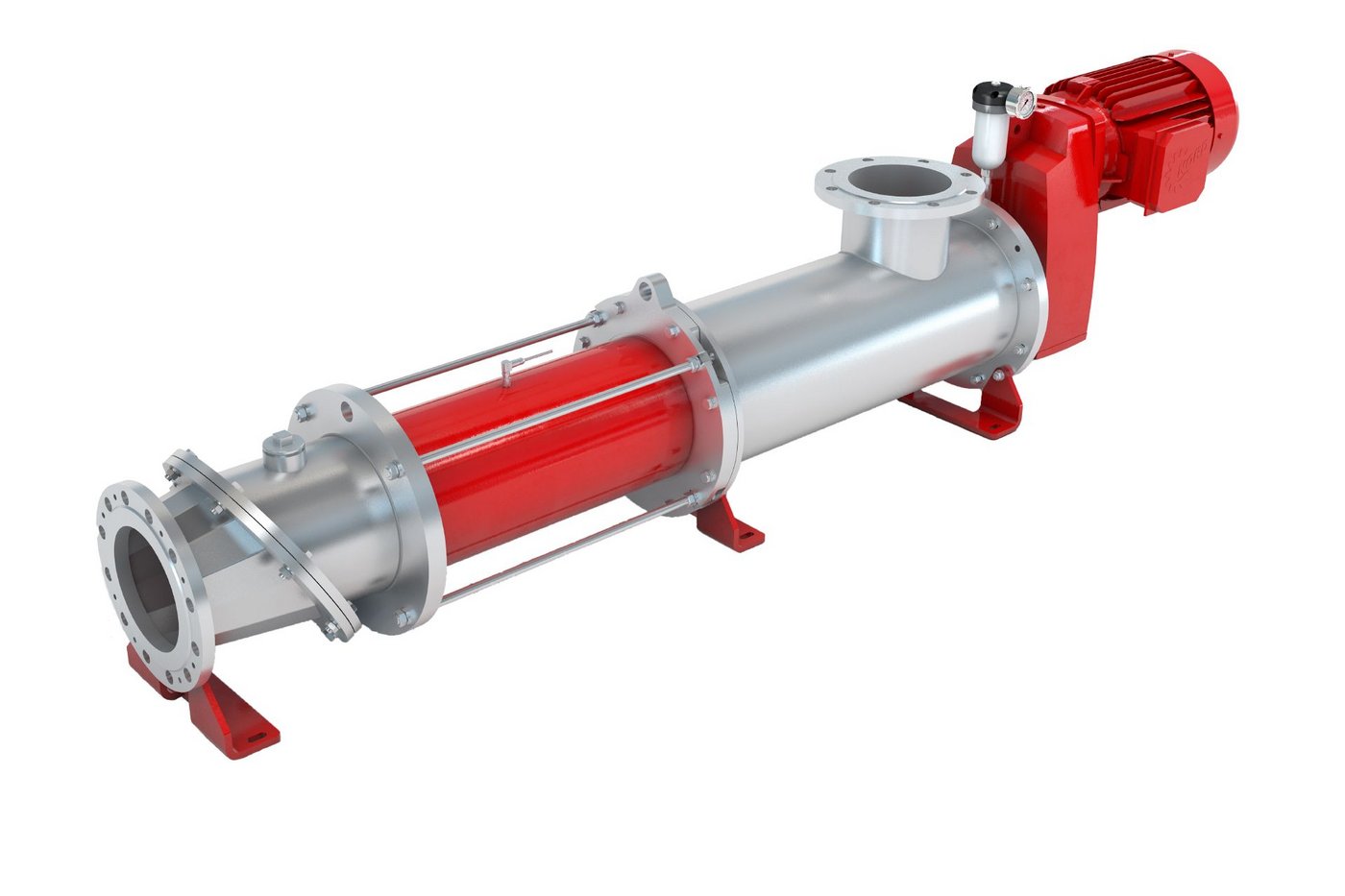

The CC55 is the compact Cavity Comfort progressive cavity pump for applications with medium delivery rates. The generously sized cardan shaft makes the pump sturdy and reliable even in challenging applications; for example when pumping abrasive sludges, highly viscous suspensions or digestates. Thanks to the large free passage, the CC55 progressive cavity pump is not sensitive to foreign matter. Service and maintenance work is quick and easy thanks to the innovative design of the CC series.

Downloads

The powerful and easy to maintain progressive cavity pump

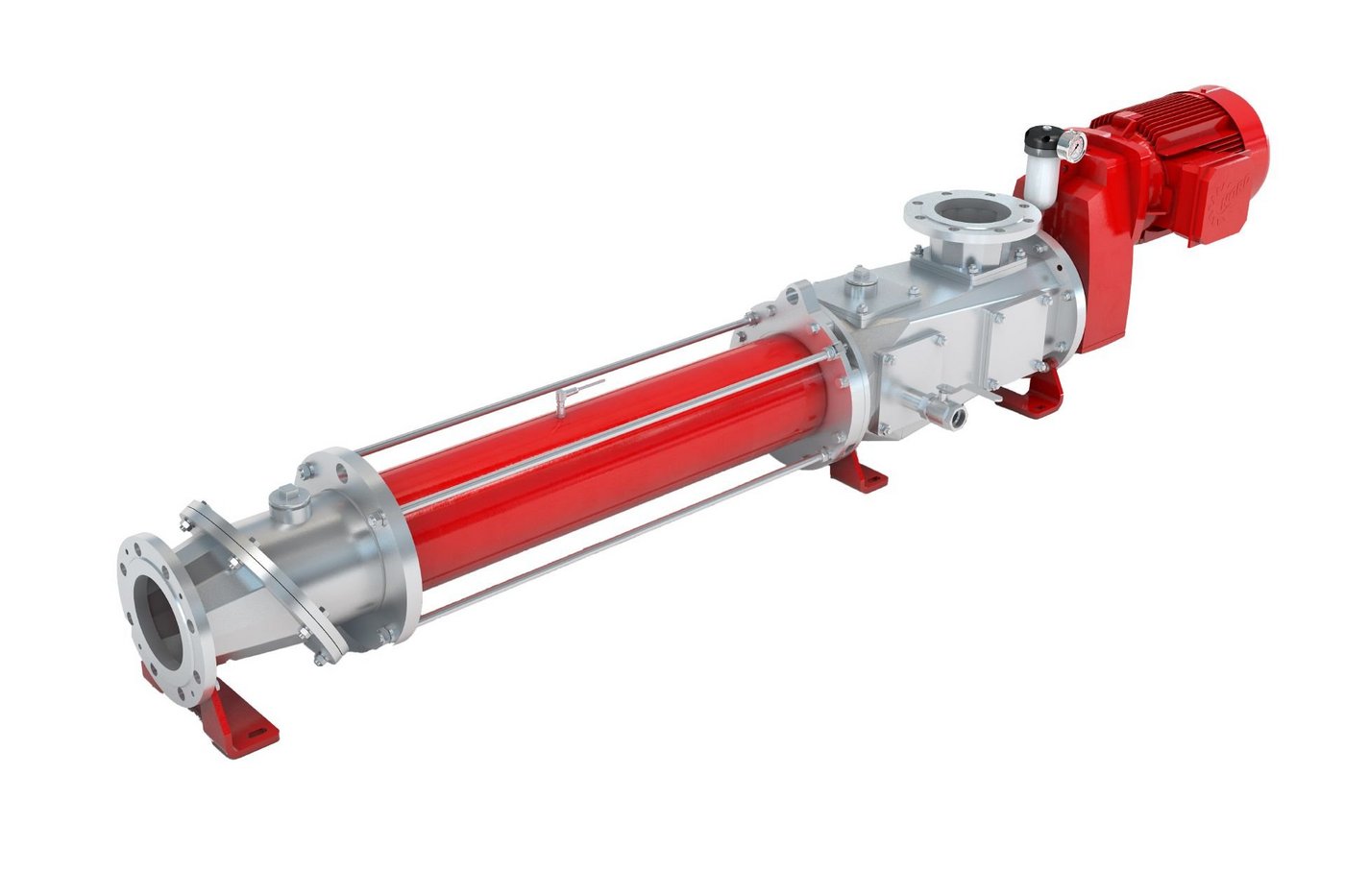

CC66

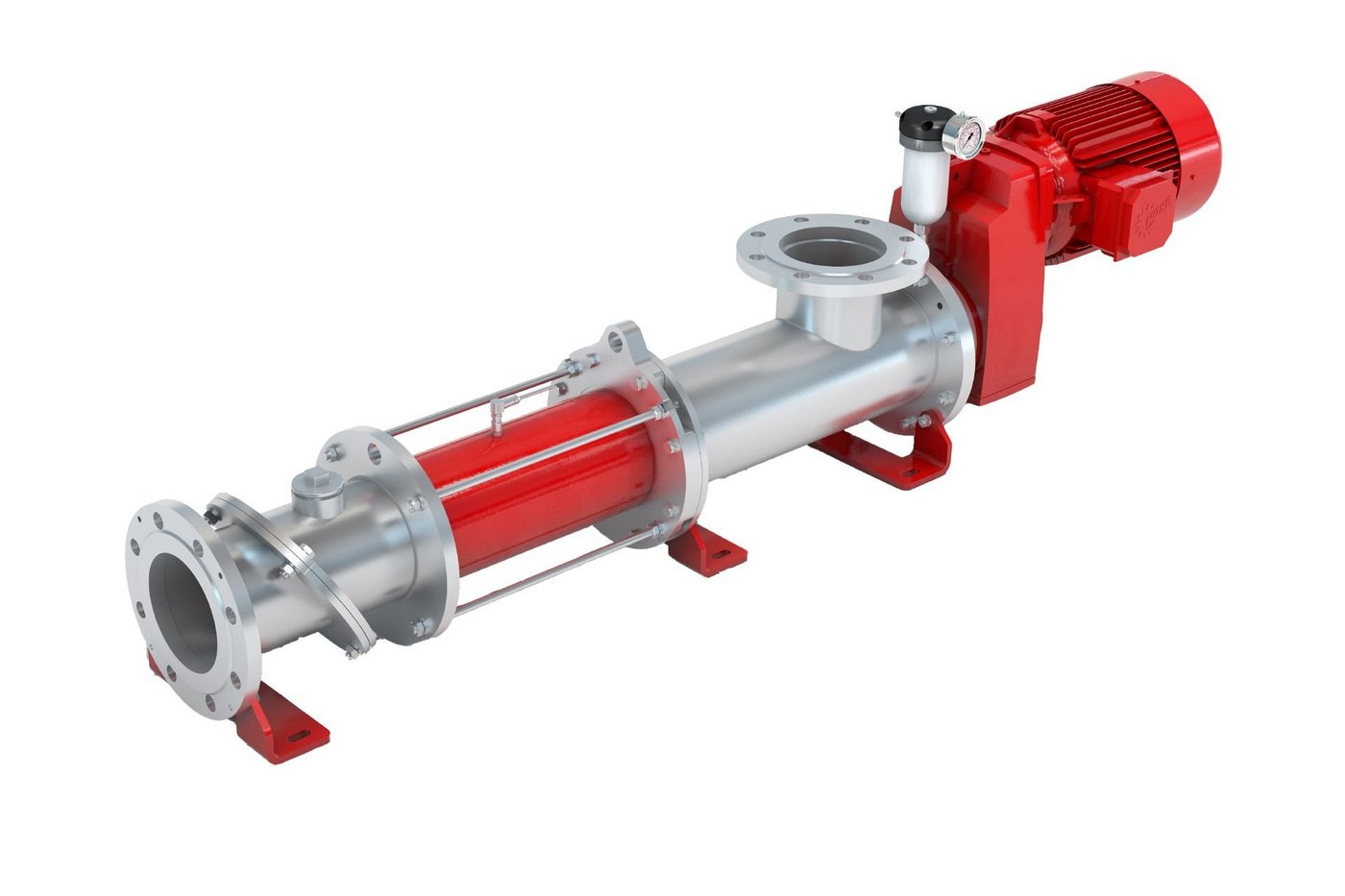

The CC66 is the powerful, user friendly and easy to maintain progressive cavity pump of the CC series. It comes into use, when media are highly viscous or abrasive as well as contain a high amount of foreign matter, which have to pumped with a high capacity and against high pressures. At the same time no long downtimes due to service and maintenance are acceptable. This can apply to e.g. the dosing of solid matter at biogas plants or the pumping of highly viscous sludges at wastewater treatment plants. For those applications the CC66 is the right choice.

Downloads

The large, easy to maintain progressive cavity pump

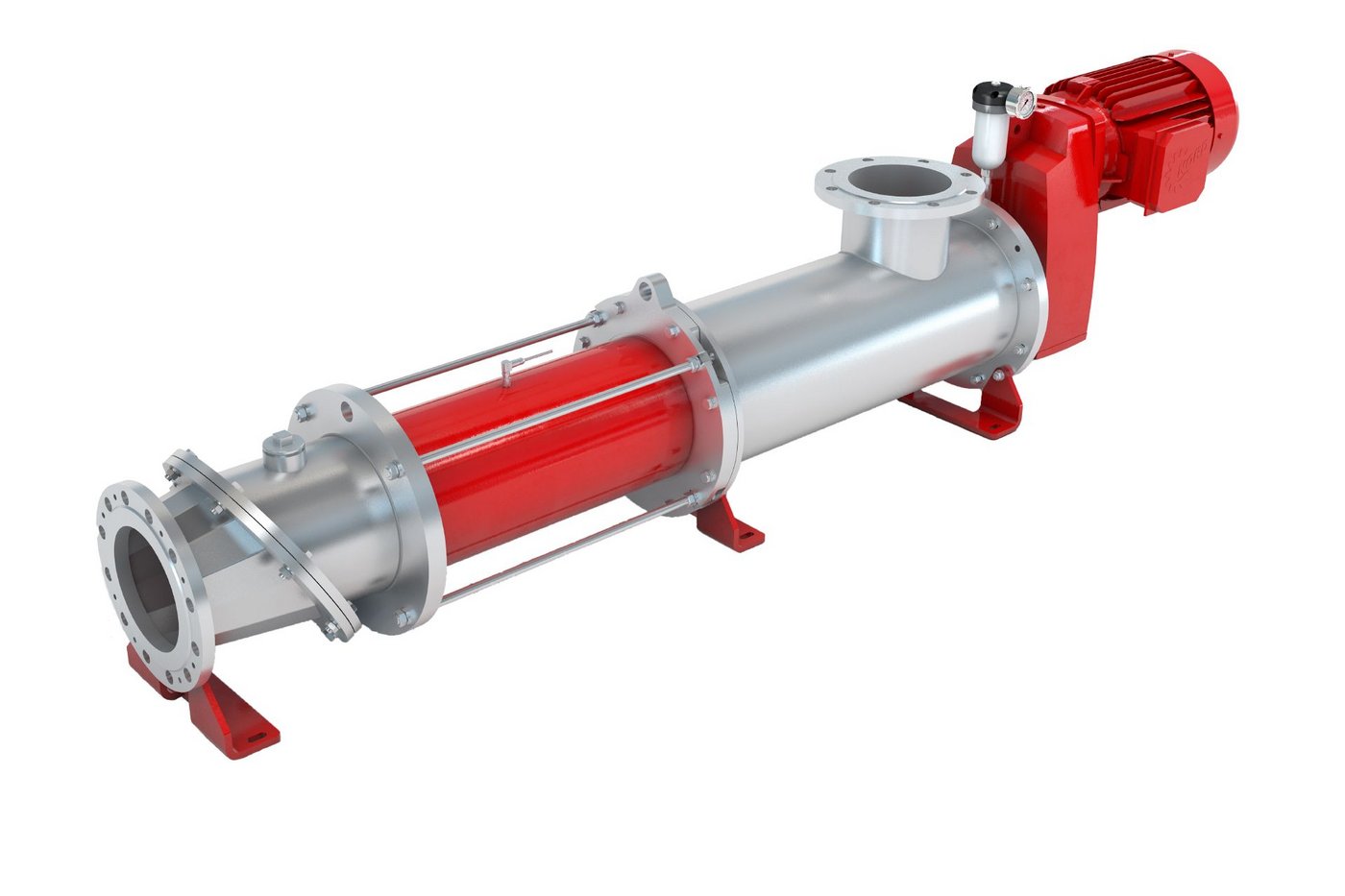

CC77

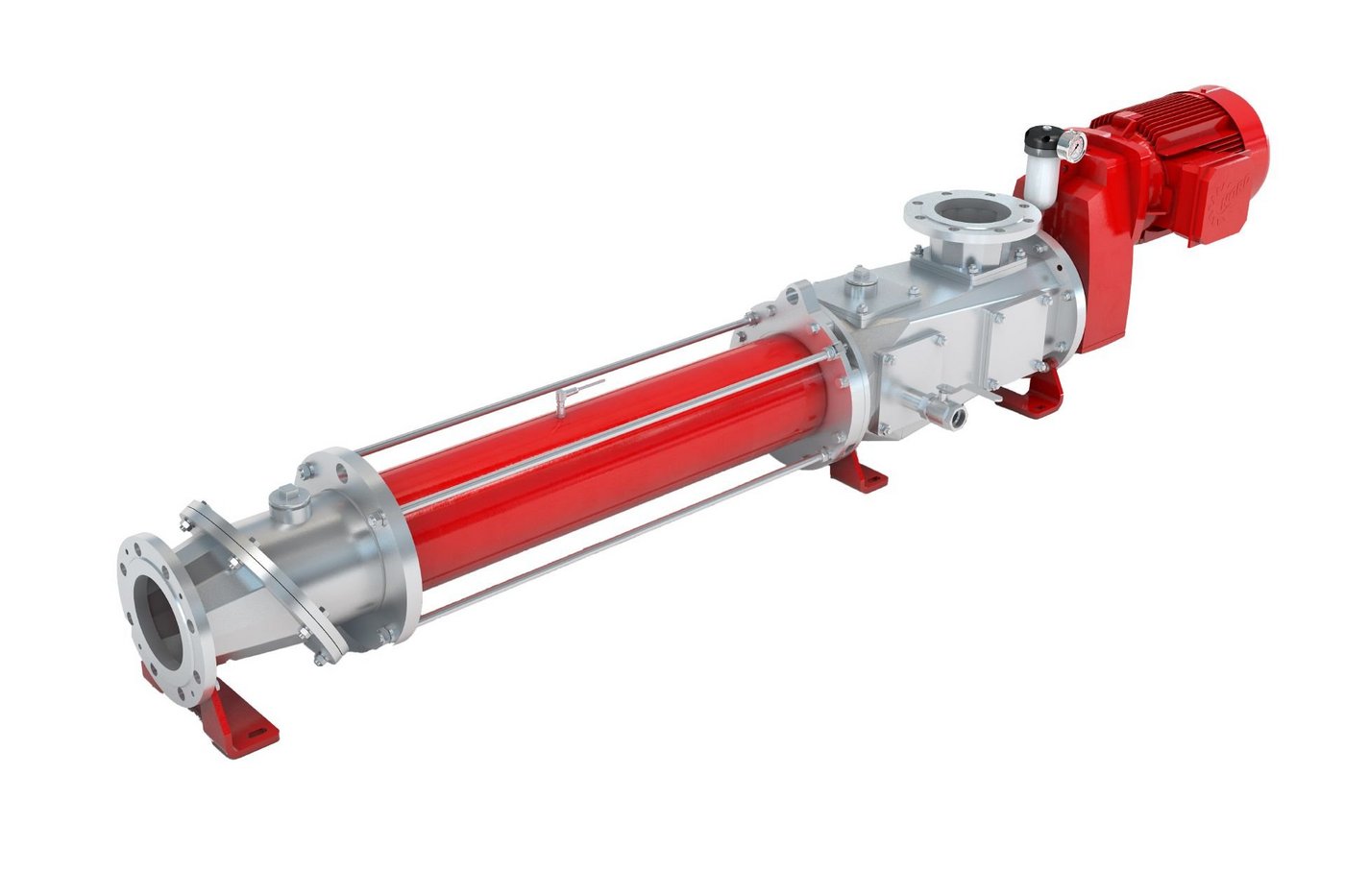

The CC77 is the largest progressive cavity pump available with the innovative QuickService design. The CC77 can pump sludges with a high foreign matter content, abrasive organic suspensions or liquid manure effectively and reliably. The large free passage also makes it extremely resistant to large-sized foreign matter and disruptive matter. At the same time, it features the quick and easy service typical of the CC series, which is not common for progressive cavity pumps of this size.

Downloads

The small, easy to maintain progressive cavity pump

CC44

The CC44 is the Vogelsang progressive cavity pump for small capacities paired with the unique advantages of the Cavity Comfort CC series. Highly viscous sludge, abrasive organic suspension or sewage is pumped efficiently. Thanks to the large free passage, it is not sensitive to foreign matter and disruptive matter. At the same time, it features the easy and quick service typical of the CC series.

Downloads

The compact, easy to maintain progressive cavity pump

CC55

The CC55 is the compact Cavity Comfort progressive cavity pump for applications with medium delivery rates. The generously sized cardan shaft makes the pump sturdy and reliable even in challenging applications; for example when pumping abrasive sludges, highly viscous suspensions or digestates. Thanks to the large free passage, the CC55 progressive cavity pump is not sensitive to foreign matter. Service and maintenance work is quick and easy thanks to the innovative design of the CC series.

Downloads

The powerful and easy to maintain progressive cavity pump

CC66

The CC66 is the powerful, user friendly and easy to maintain progressive cavity pump of the CC series. It comes into use, when media are highly viscous or abrasive as well as contain a high amount of foreign matter, which have to pumped with a high capacity and against high pressures. At the same time no long downtimes due to service and maintenance are acceptable. This can apply to e.g. the dosing of solid matter at biogas plants or the pumping of highly viscous sludges at wastewater treatment plants. For those applications the CC66 is the right choice.

Downloads

The large, easy to maintain progressive cavity pump

CC77

The CC77 is the largest progressive cavity pump available with the innovative QuickService design. The CC77 can pump sludges with a high foreign matter content, abrasive organic suspensions or liquid manure effectively and reliably. The large free passage also makes it extremely resistant to large-sized foreign matter and disruptive matter. At the same time, it features the quick and easy service typical of the CC series, which is not common for progressive cavity pumps of this size.

Downloads

Features of the CC series

Options of the CC series

The easy to use CavityComfort pump for freshly mashed organic suspensions

Progressive cavity pumps of the CC series for biogas applications

The CC series was developed for harsh applications in which long downtimes for service and maintenance work are not acceptable – such as pumping freshly mashed organic suspensions, i.e. highly viscous media loaded with large quantities of fibrous solid matter.

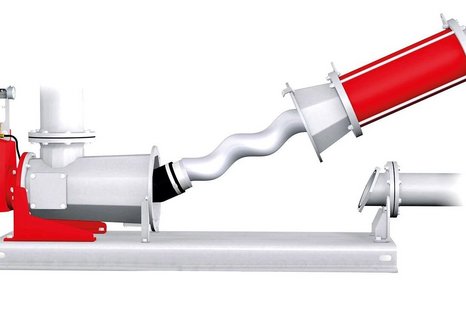

The QuickService design is one-of-a-kind. Vogelsang has managed to decisively improve the tried-and-tested concept of the progressive cavity pump: Compared to conventional progressive cavity pumps, service and maintenance work is significantly quicker and takes up less space, because the innovative QuickService design means there is no need to disassemble parts of the pipe.

All essential parts, including the gasket, can be quickly and easily changed, so the pump is soon operational again. Even the mechanical seal in the trusted Quality Cartridge design is easy to replace in the CC series.

At the same time, attention was paid to creating a sturdy and fault-resistant design; features that are essential for biogas plants: The large free passage is ensured over the entire length, preventing clogging and blockages caused by coarse disruptive matter such as foil residue and wood. The sturdy design of the drive line, including the cardan shaft, makes the progressive cavity pumps in the CC series ideal for high dry matter content and media loaded with foreign matter. This means that the unique overall concept of the CC series ensures long service lives, short downtimes for service and maintenance, and low operating costs for your biogas plants.

Downloads