Easy to use rotary lobe pump

IQ series

- The easiest maintenance, rapid onsite service

- Quick, optimum access to the pumping elements

- Self-priming and resistant to dry running

- Easy and flexible to integrate

Service and handling made even easier

The highly economical IQ series for maximum performance yet less work

With its design reduced to just a few individual elements that makes handling even easier compared to rotary lobe pumps of the VX series, the Vogelsang IQ series is proof that even successful technology is worth redesigning.

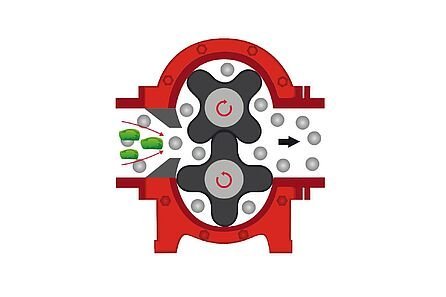

IQ series rotary lobe pumps are also equipped with the tried and-tested pulsation-free HiFlo rotary lobe. The unique InjectionSystem makes it just as resistant to foreign matter as it is to dry running – and protects the lobe from damage, thereby ensuring a uniform pumping speed. In contrast to the pumps of the VX series, the pump housing of the IQ series consists of just a single component; it can be dismounted with just a few movements, giving access to the pump elements, while the pump remains firmly screwed into the pipe.

Models of the IQ series

The universal rotary lobe pump

Rotary lobe pump IQ112

Pumps in the IQ112 series are the ideal solution for when quick maintenance, cost-saving service, easy handling and maximum availability is needed. With capacities of up to 78 m3/h and pressures up to 7 bar, this is the cost-effective and easiest to maintain solution for difficult media such as primary sludge or media containing coarse matter (e.g. contaminated used oil).

Downloads

The powerful rotary lobe pump

Rotary lobe pump IQ152

The pump IQ152 is ideal for greater capacities up to 154 m3/h and pressures up to

7 bar. It can be used in sewage and wastewater treatment plants as well as for industry applications, where a high availability thanks to reduced maintenance is needed.

Downloads

The universal rotary lobe pump

Rotary lobe pump IQ112

Pumps in the IQ112 series are the ideal solution for when quick maintenance, cost-saving service, easy handling and maximum availability is needed. With capacities of up to 78 m3/h and pressures up to 7 bar, this is the cost-effective and easiest to maintain solution for difficult media such as primary sludge or media containing coarse matter (e.g. contaminated used oil).

Downloads

The powerful rotary lobe pump

Rotary lobe pump IQ152

The pump IQ152 is ideal for greater capacities up to 154 m3/h and pressures up to

7 bar. It can be used in sewage and wastewater treatment plants as well as for industry applications, where a high availability thanks to reduced maintenance is needed.

Downloads

Features of the IQ series

Options of the IQ series