Pumps as the core element of supply and disposal systems

Rotary lobe pumps of the VX series for applications related to railway, bus and boat

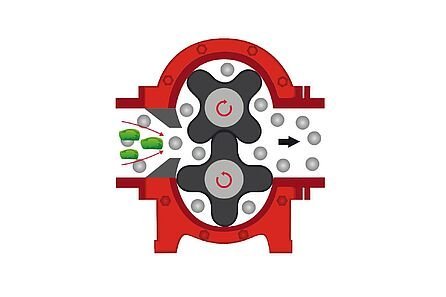

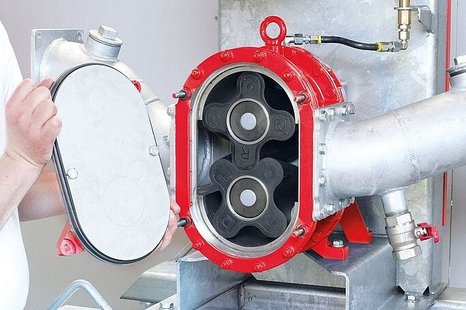

The rotary lobe pumps of the VX series are the centerpiece of our wastewater disposal and fresh water supply systems for the rail, bus and boat segments. Thanks to their ability to pump viscous fluids with a high foreign matter content, the VX series pumps are ideal for these applications. The rotary lobe pumps in the VX series can be used as the main component of a double pump station, a T-system or a supply cabinet for rail transportation. They can also be installed in ports in the PierPump form in order to pump away wastewater or bilge water, or as the RoadPump in bus stations, in depots or gas stations and rest stops on the highway. Vogelsang pumps are very compact, sturdy and exceptionally powerful, which makes the system very effective. Thanks to the QuickService concept, any maintenance work necessary can be completed quickly and easily. For outdoor installations, the systems can be heated and installed in a stainless steel version.

Downloads

Features of the VX series

Options of the VX series