Pump systems for special cases

Pumps and more

Some pumping processes require additional functions. But generally, this leads to problems relating to issues of space, installation possibilities etc. With pump systems from Vogelsang, our customers benefit from powerful pump technology combined with that certain something extra.

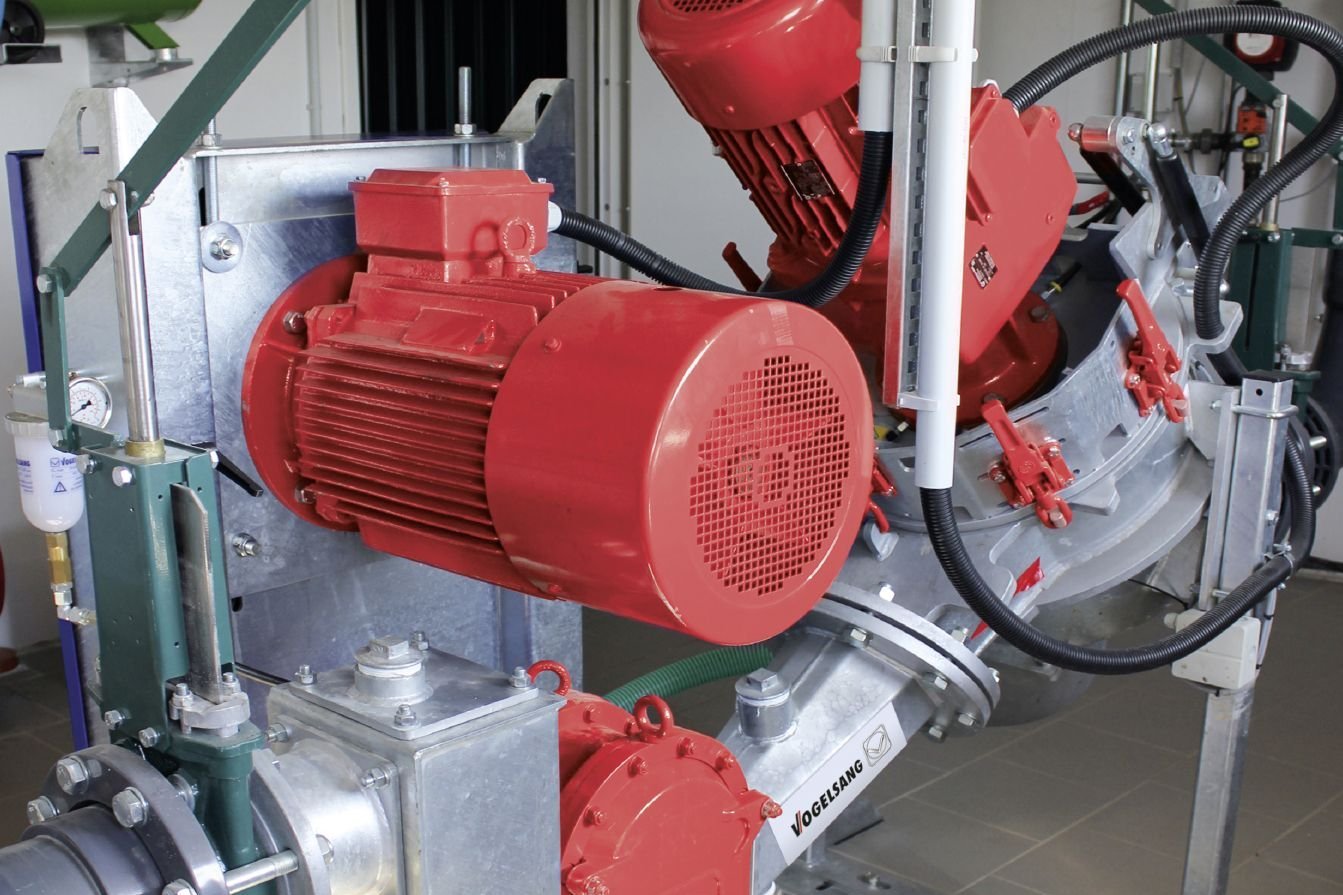

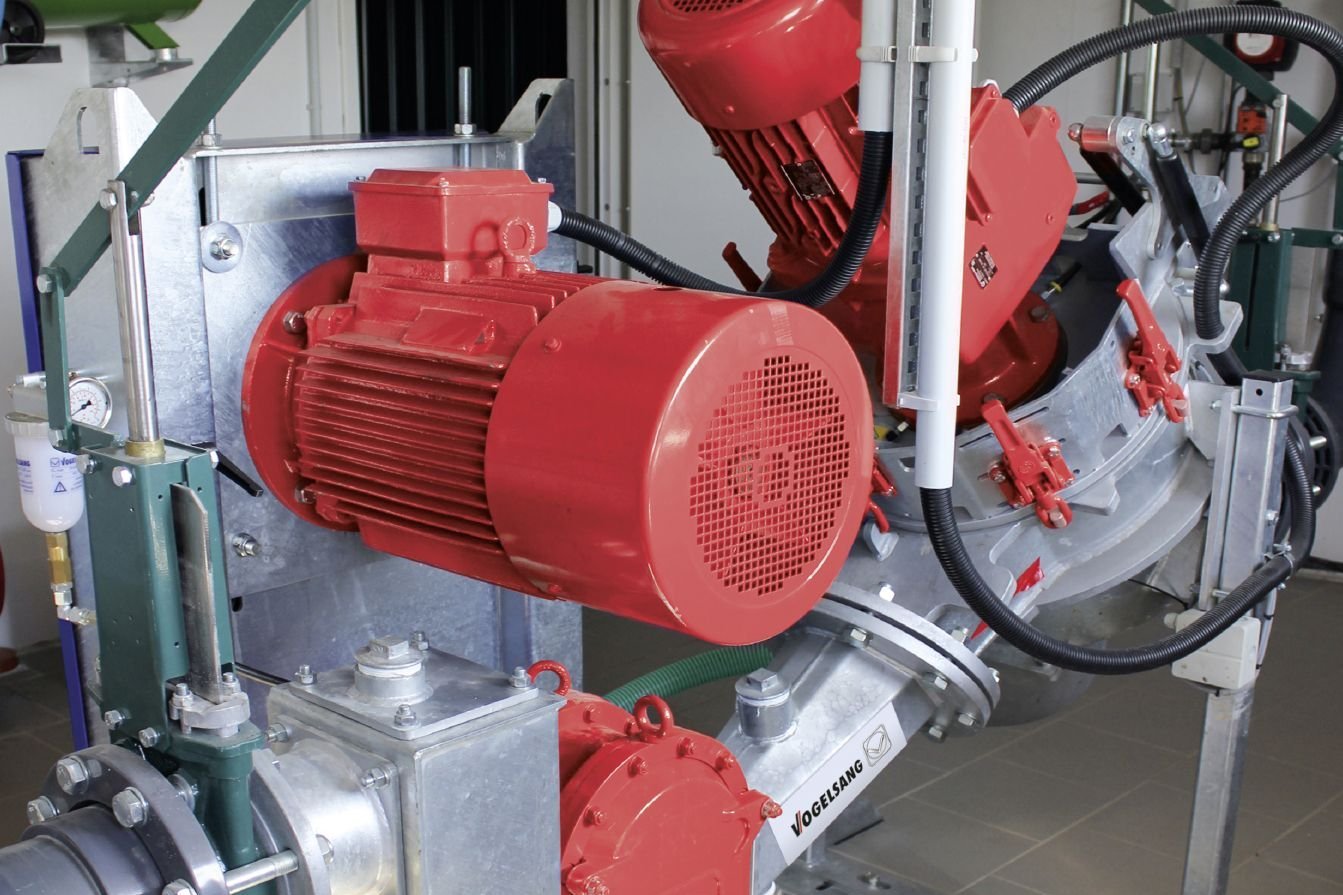

Designed specifically for the biogas sector, our pump systems consisting of a macerator and rotary lobe pump (BioCut) or progressive cavity pump (CC- Cut) can shred, pump and separate out foreign matter in a single process.

The perfect pump system for any application

Combining different Vogelsang products is especially useful when it comes to typical problems such as media with high foreign matter content or a lack of space. For example, a cutter or a foreign matter separator can be connected upstream from a pump and they can be installed together as a complete unit. These coordinated, space-saving product combinations provide useful overall solutions that can be individually adapted to solve each specific application.

The universal pump system

BioCut®

- Cost-effective pumping thanks to optimally coordinated components

- Reliable conveying of a wide range of challenging media

- Separation of heavy material and treatment of disruptive matter before the pump

- Compact design and minimal space requirements

- Service and maintenance can be performed quickly and easily on site

The powerful pump system

CC-Cut

- Efficient pumping thanks to optimally coordinated pump and cutter

- Reliable, trouble-free pumping of challenging and highly viscous media

- Treatment of disruptive matter and separating out of heavy material before the pump

- Low space requirements thanks to extremely compact design

- Maintenance and changing of parts can be performed quickly and easily on site

The universal pump system

BioCut®

- Cost-effective pumping thanks to optimally coordinated components

- Reliable conveying of a wide range of challenging media

- Separation of heavy material and treatment of disruptive matter before the pump

- Compact design and minimal space requirements

- Service and maintenance can be performed quickly and easily on site

The powerful pump system

CC-Cut

- Efficient pumping thanks to optimally coordinated pump and cutter

- Reliable, trouble-free pumping of challenging and highly viscous media

- Treatment of disruptive matter and separating out of heavy material before the pump

- Low space requirements thanks to extremely compact design

- Maintenance and changing of parts can be performed quickly and easily on site