"As efficiency and sustainability become increasingly important, optimal substrate processing is gaining strategic significance. With our solutions, we enable biogas plant operators to increase output, reduce operating costs, and ensure their plants remain efficient and future-proof," says Michael Brinkmann, Chief Sales Officer at Vogelsang.

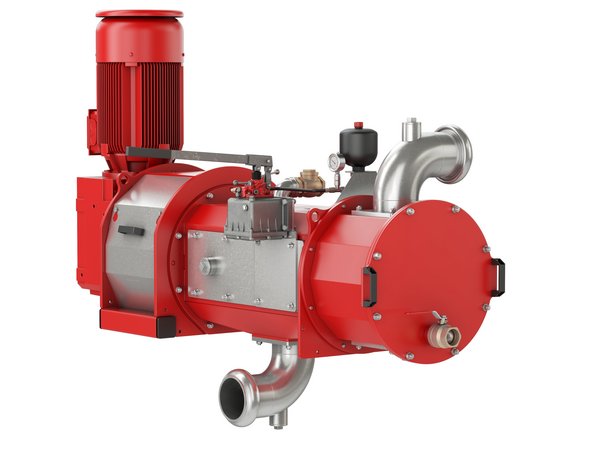

MixXPump solid matter feeder – with HiCone as the key element

The MixXPump enables operators to set up their biogas plant's feeding technology in an efficient and modern way.

Brinkmann: "The MixXPump extends our product portfolio with a compact solid matter feeding system. Designed for easy-to-process substrates such as maize silage, its flat design allows for effortless integration into both new and existing biogas plants."

The central element of the MixXPump is the HiCone conical progressive cavity pump, which reliably conveys the previously prepared and mashed solid matter into the digester as a suspension. Its conical rotor-stator geometry makes it possible to compensate for wear on the conveying elements through precise readjustment – costly and time-consuming part changes are no longer necessary. However, if the rotor and stator need to be replaced after a long period of operation, Vogelsang's QuickService concept makes this much easier: downtimes are reduced to just a few hours – the feeding of the digester continues almost without interruption. This ensures a stable fermentation process and a consistently high gas yield.

A separate exhibit on the HiCone pump illustrates the functionality and specific application benefits of the technology to trade fair visitors.

XSplit XS30-80: needs-based separation technology on a large scale

At its trade fair stand, Vogelsang will also be exhibiting the XSplit press screw separator in a new size, which has a throughput capacity of up to 175 cubic meters per hour. The XSplit XS30-80 is specially designed for use in large biogas plants and agricultural operations. As the largest model in its range, it offers users who need to separate large quantities of digestate or liquid manure a reliable and needs-based solution. Its maintenance-friendly design enables significantly shorter service times than is the case for conventional press screw separators and the easy replacement of spare parts. The modular, three-part sieve also enables the replacement of just the worn part. In addition, the VarioAdjust hydraulic adjustment system allows the contact pressure to be flexibly adjusted during operation. This enables the best possible adaptation to the medium to be separated and the needs-based adjustment of the dry substance content.

PreMix IC: compact solid matter feeder as a premium solution

At the trade fair, Vogelsang will be presenting the PreMix IC, the new generation from the PreMix series. The reliable liquid feeding system combines four work steps in one compact unit. Users achieve increased gas yields with reduced internal energy requirements – even with challenging solid matter and under varying conditions. In the modified PreMix IC, Vogelsang combines the HiCone conical progressive cavity pump with the RotaCut RCX wet cutter. Its powerful cutting unit reliably shreds even fibrous solid matter. The solid matter feeder separates out any heavy material contained in the input materials and discharges it during operation with the optional Debris Removal System (DRS).

In addition, the control unit is equipped with improved software and a modernized user interface. This makes the system more efficient and user-friendly. The Performance Control Unit (PCU) automatically controls the PreMix within the optimum range to ensure efficient solid matter feeding throughout. Overall, the modified liquid feeding system stands for an even higher feed rate, less wear, a longer service life, and lower energy and operating costs.